Correct. And being both certified to and having done SI on thin-film intumescent materials, I am confounded on how the testing would be done. Following AWCI Tech Manual 12-B, the testing apparatus only work with ferrous substrate. I am positive that there are other means and methods for testing on non-ferrous substrates, but I lack familiarity and would suspect that SI was not performed in this application, otherwise a report could be provided to the building inspector and likely assuage his concerns.Click through the links, and you'll see that special inspection is required at installation to confirm proper application.

-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Introduction and quick question

- Thread starter latees40

- Start date

- Featured

Inspector Gadget

REGISTERED

Not a UL(C) assembly.Just going to leave this here:

I used to respect ICC.....

UL / UL(C) is not required. UL is just one of the many testing/accreditation agencies.Not a UL(C) assembly.

While I do not have the utmost confidence in a number of ICC-ES reports I have seen, the code requires testing per ASTM E119 or UL 263. It is up to the code official if the testing/accreditation agency (UL, GA, ICC-ES, etc.) is approved, which should be contingent on following the appropriate test procedures.

2021 IBC 703.2.1 Tested Assemblies

A fire-resistance rating of building elements, components or assemblies shall be determined by the test procedures set forth in ASTM E119 or UL 263. The fire-resistance rating of penetrations and fire-resistant joint systems shall be determined in accordance with Sections 714 and 715, respectively.Inspector Gadget

REGISTERED

UL / UL(C) is not required. UL is just one of the many testing/accreditation agencies.

That makes things ... murky, doesn't it?

We're limited to - for small buildings, assemblies outlined in the small buildings section of code, ULC-listed assemblies, and calculations made under the dark part of Canadian Code that deals with general "A plus B plus C" calculations called appendix D.

For large/complex buildings, Appendix D or ULC are the only acceptable options.

steveray

SAWHORSE

I'm going to chime in as well: I have yet to see *any* UL(C)-listed assembly that uses intumescent paint to achieve a fire-resistance rating.

I have seen a paint-like intumescent product applied to site-batched sprayfoam to provide a modest fire barrier equivalent to protecting with plywood or OSB, but that's a totally different beast.

Just because somebody read a label saying "this will do X" doesn't mean it meets Code.

Just because the plan checker and the first inspector did not identify a code violation what makes you believe that you do not have a code violation?

Inspector Gadget

REGISTERED

Just because the plan checker and the first inspector did not identify a code violation what makes you believe that you do not have a code violation?

This appears like you're trying to make a point. If so, you need to do a better job.

Yankee Chronicler

SAWHORSE

Click through the links, and you'll see that special inspection is required at installation to confirm proper application.

Yes. And the fire-resistance rating is a function of the applied dry-film thickness. That's what the special inspector has to verify, just as with any spray-applied fire-resistive material.

Paul Sweet

SAWHORSE

60 mils is about 1/16". That will take more than a couple coats. $20.50 per quart at 27 SF per gallon = $3 per square foot + labor.

I was involved on a project where the A/E specified an intumescent coating on exposed steel to get a 2 hour fire rating. It wasn't a very smooth finish.

I was involved on a project where the A/E specified an intumescent coating on exposed steel to get a 2 hour fire rating. It wasn't a very smooth finish.

Plus, these thin-film intumescent products must be maintained (i.e. damage such as scratches, dings, etc. are a problem) and often cannot be exposed to moisture/humidity, UV light, or other degrading elements. This can be further complicated if the manufacturer does not permit further coatings, such as paint or adhereed finishes, on top of these coatings.60 mils is about 1/16". That will take more than a couple coats. $20.50 per quart at 27 SF per gallon = $3 per square foot + labor.

I was involved on a project where the A/E specified an intumescent coating on exposed steel to get a 2 hour fire rating. It wasn't a very smooth finish.

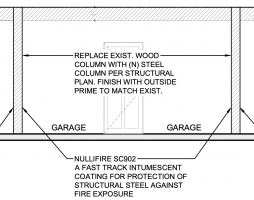

I am currently researching intumescent coatings. The plans call for a product call Nullifire SC902. It is (or was) manufactured in the UK and has a CE approval but no North American Listing. I have not been able to contact them and I am not convinced that they are still in business.Plus, these thin-film intumescent products must be maintained (i.e. damage such as scratches, dings, etc. are a problem) and often cannot be exposed to moisture/humidity, UV light, or other degrading elements. This can be further complicated if the manufacturer does not permit further coatings, such as paint or adhereed finishes, on top of these coatings.

I have found other UL and ICC listed products. So far, none are allowed exposed to the elements but several can accept a polyurethane topcoat. The product that steveray posted is not one of them.

walker.t

SAWHORSE

I investigated using intumescent paint in a project a number of years ago, owner of the company talked to me about the product and process. He said they have data for the painters regarding spray nozzles and the amount of product to be applied for the given area to achieve the required thickness. The application had to be inspected by a third-party inspector then their company issued a document regarding the rating. Owner didn’t use the product so I can’t comment on how things went.

There are a bunch of manufacturers of intumescent coatings. I talked to three. The required coating thickness varied from 26mil to 100mil. One would not allow it outdoors and the other two had a topcoat that would allow it outdoors. All required a proprietary primer. They all required a certain paint sprayer and one could be trowel applied.

The material comes in five gallon containers and the cost would vary from $600 to $1100 for primer, paint and topcoat. Add the special inspector and it climbs $350.

My role is as an advisor. The contractor opted to use a stucco wrap instead of the intumescent coating. I figure that cost wise, there wasn't a huge difference.

One bit of information that I found to be interesting is that the coating will expand 200 times when exposed to fire.

The material comes in five gallon containers and the cost would vary from $600 to $1100 for primer, paint and topcoat. Add the special inspector and it climbs $350.

My role is as an advisor. The contractor opted to use a stucco wrap instead of the intumescent coating. I figure that cost wise, there wasn't a huge difference.

One bit of information that I found to be interesting is that the coating will expand 200 times when exposed to fire.

Last edited: