Energystar

SAWHORSE

R802.7 Cutting, drilling and notching.

In my area current economics have caused many builders to now opt for stick-framing over trusses. This section of the IRC has been discussed at length by this forum, yet no one has come up with a complete explanation of its apparent contradictions. There are two separate but related issues that have been discussed: 1) The depth of notch limit and 2) Toe support.

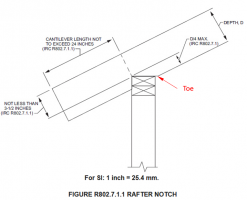

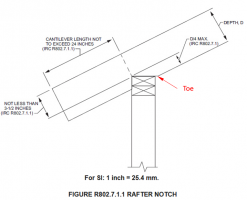

The diagram below makes no sense to me except for the part about the rafter cantilever. Why would the code limit the depth of the notch on a rafter to D/4 as measured in the figure below? I have seen rafters framed off of subfloors where the notch was nearly full depth. Jack rafters for overlays are full depth. If we ignore the tail, and the toe of the birdsmouth is solidly supported, what’s the problem?

Hip and Valley Rafters

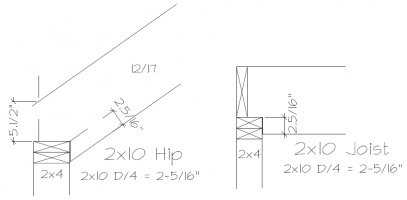

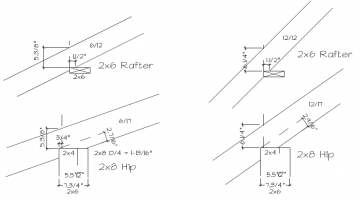

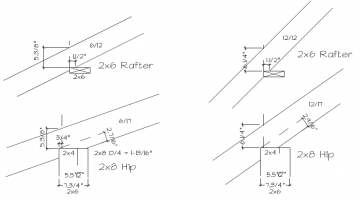

The reason I insist on beating this horse is that if one follows the code precisely using the smallest bearing allowed (1.5”) for rafters and then uses the next size up (2” nominal larger) as required for the hip, it is impossible (using standard techniques) to make the notch on the hip less than D/4 regardless of the pitch. See the figure below. Interestingly, it is also impossible to support the toe unless using 2x6 walls or using a 12/12 pitch for 2x4 walls.

One must assume the code is not banning the common practice of stick-framing. Are hip and valley rafters, therefore exempt? If one uses engineered material like an LSL or LVL, it is possible to engineer your way out of these issues, but with conventional lumber it is much more difficult. There are many videos online that describe techniques of fabricating hip and valley rafters. All seem to go out of their way to avoid discussing these issues while all appear to violate the D/4 limit as shown above.

If we read R802.7.1 carefully, it appears to refer to the overhang cantilever in figure R802.7.1.1 as an exception, “. . . except that cantilevered portions of rafters shall be permitted in accordance with Section R802.7.1.1.”

R802.7.1 also refers to another section of the code in Floors, R502.8.1, where the following figure shows the allowable notching of floor joists. Again, they use the D/4 limit. It doesn’t take an engineer to see that on the left side of this figure the notch will definitely weaken the joist. The deeper the notch, the greater the impact.

The general statement it makes regarding structural members is, “Notches at the end of the member shall not exceed one-fourth the depth of the member.” I would suggest that, as it pertains to rafters, this figure would be analogous to an unsupported toe of the rafter as shown below with the D/4 dimension changed to reflect the impact to the weakening of the rafter.

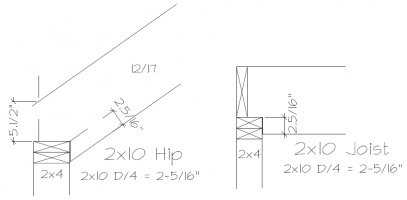

This is a figure comparing 2x10’s notched to the maximum depth of D/4. The figure on the right is code compliant. Is the figure on the left? Many would argue that neither are “proper” or at least ideal and should be avoided. The question is, is this what the ICC is attempting to say? The way we measure the depth of the notch should be related to its impact on the structural integrity of the rafter.

In my area current economics have caused many builders to now opt for stick-framing over trusses. This section of the IRC has been discussed at length by this forum, yet no one has come up with a complete explanation of its apparent contradictions. There are two separate but related issues that have been discussed: 1) The depth of notch limit and 2) Toe support.

The diagram below makes no sense to me except for the part about the rafter cantilever. Why would the code limit the depth of the notch on a rafter to D/4 as measured in the figure below? I have seen rafters framed off of subfloors where the notch was nearly full depth. Jack rafters for overlays are full depth. If we ignore the tail, and the toe of the birdsmouth is solidly supported, what’s the problem?

Hip and Valley Rafters

The reason I insist on beating this horse is that if one follows the code precisely using the smallest bearing allowed (1.5”) for rafters and then uses the next size up (2” nominal larger) as required for the hip, it is impossible (using standard techniques) to make the notch on the hip less than D/4 regardless of the pitch. See the figure below. Interestingly, it is also impossible to support the toe unless using 2x6 walls or using a 12/12 pitch for 2x4 walls.

One must assume the code is not banning the common practice of stick-framing. Are hip and valley rafters, therefore exempt? If one uses engineered material like an LSL or LVL, it is possible to engineer your way out of these issues, but with conventional lumber it is much more difficult. There are many videos online that describe techniques of fabricating hip and valley rafters. All seem to go out of their way to avoid discussing these issues while all appear to violate the D/4 limit as shown above.

If we read R802.7.1 carefully, it appears to refer to the overhang cantilever in figure R802.7.1.1 as an exception, “. . . except that cantilevered portions of rafters shall be permitted in accordance with Section R802.7.1.1.”

R802.7.1 also refers to another section of the code in Floors, R502.8.1, where the following figure shows the allowable notching of floor joists. Again, they use the D/4 limit. It doesn’t take an engineer to see that on the left side of this figure the notch will definitely weaken the joist. The deeper the notch, the greater the impact.

The general statement it makes regarding structural members is, “Notches at the end of the member shall not exceed one-fourth the depth of the member.” I would suggest that, as it pertains to rafters, this figure would be analogous to an unsupported toe of the rafter as shown below with the D/4 dimension changed to reflect the impact to the weakening of the rafter.

This is a figure comparing 2x10’s notched to the maximum depth of D/4. The figure on the right is code compliant. Is the figure on the left? Many would argue that neither are “proper” or at least ideal and should be avoided. The question is, is this what the ICC is attempting to say? The way we measure the depth of the notch should be related to its impact on the structural integrity of the rafter.