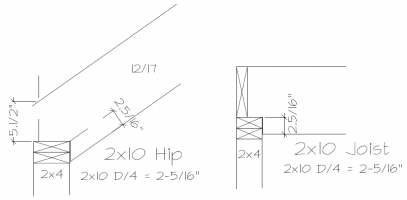

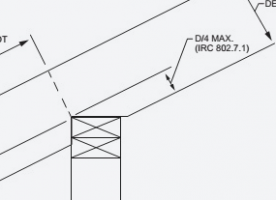

R802.7.1 also refers to another section of the code in Floors, R502.8.1, where the following figure shows the allowable notching of floor joists. Again, they use the D/4 limit. It doesn’t take an engineer to see that on the left side of this figure the notch will definitely weaken the joist. The deeper the notch, the greater the impact.

View attachment 10889

Actually... it's engineering specifically that says the D/4 notch at bearing is fine. A 2x10 notched down to the height of a 2x8 at bearing still gets all the credit as a 2x10 for the span and it makes perfect sense when looked through the lens of engineering.

The two stresses a spanning member experiences are shear and bending. Shear is greatest at bearing and bending is greatest in the middle of span. Bending stress is what creates deflection and is the first limiting factor to maximum span. Long before shear becomes too great at the bearing location, you have already exceeded deflection through bending.

This is why you cannot notch the middle third. Bending is resisted in the top and bottom of the joist and it's maximum at the center (middle third).

Shear on the other hand is greatest at the bearing location. For example, where a 2x10 is required for a span in order to stay within deflection, a 2x8 is plenty large enough to resist the shear at bearing from the load collected over that span.

The way the notching limits are presented for rafters will essentially ensure the heel is supported when using the minimum required bearing area of 1.5 inches for prescriptive designs. I agree that the information might not be presented in the easiest to understand manner, but the science is solid. Proposals for 2027 are due January 2025.

Here is an article of mine that explains the Science of Simple Spans that is the root of allowable notching: https://www.finehomebuilding.com/project-guides/framing/the-science-of-simple-spans

Here is a clip of mine explaining bending, shear and notching limits.