-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Roof frame pics to make you smile

- Thread starter Sifu

- Start date

That's happened to me. Not that I'm complaining but sometimes I think they do it on purpose.DRP said:There is always the possibility I was fixating on a dangling tit.

Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,572

If memory serves, in addition to the possibly over-zealous over-notched condition, my list for the roof framing contained over-spanned rafters, missing and improper rafter ties, over-cut and unsupported hip and valley cuts at the top and bottom and incomplete load path to the fdtn. I did not list missing attachment of the roof to the foundation but as far as I know we have no prescriptive code for that here other than the hold down nails, I will re-visit that one though to be sure. I also did not list missing frieze blocks. I am not 100% sure what you refer to but if it is the blocking between the CJ I don't think they are required on a 2x8 rafter. I don't know if the 2x4 is nailed to the CJ or not, I will check on that if given the opportunity. Personally, I don't think this type of framing is particularly neat and it leads to multiple connection points that I think make an inspection less clean but I have to take baby steps and tackle the less ambiguous items.

globe trekker

REGISTERED

- Joined

- Oct 19, 2009

- Messages

- 1,739

IMO, I would not be comfortable with cutting more out of the rafter as *DRP*

suggested. I DO like the idea of placing additional framing / bracing next to

the overnotched one though, and securely & correctly nailing it to the ceiling

joists.

Because the roof rafter is overnotched, are you comfortable with telling

them how to repair it (as you or the Forum members think), or would

requiring a RDP be more prudent? Just asking...

suggested. I DO like the idea of placing additional framing / bracing next to

the overnotched one though, and securely & correctly nailing it to the ceiling

joists.

Because the roof rafter is overnotched, are you comfortable with telling

them how to repair it (as you or the Forum members think), or would

requiring a RDP be more prudent? Just asking...

Last edited by a moderator:

Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,572

As a rule I don't recommend corrective repairs like that. I will recommend a correction when it is supported by the code but when it reaches the engineering stage and/or a stage about which I don't know enough (obviously, like this one turned out to be) I stay clear if I can. I don't have the training nor the insurance nor the income of a DP. At first I thought EVERY rafter was notched 50%, now it may be that some of them are slightly over-notched. If it were the only problem he had I might try to help out by giving him an option I would accept, though keep in mind I was wrong to start with! Since he has multiple other issues and he has already supposedly retained a DP I will let the DP handle it. There were corrective actions he could have taken to cover a lot of his issues had he chosen that path. He chose a different path, he ignored the failed inspection, ignored the required insulation inspection, ignored the stop-work order and claims to have retained a DP. And, unfortunately I have too many other similar issues to deal with to chase him around and tell him how to build his house. Like I always tell the owner/contractor; when you elect to be your own contractor you may save money but the trade off is the knowlege you might miss out on from a pro, and it may cost you more in the long run.

dhengr

Bronze Member

Globe trekker:

The dangling tit that DRP suggests cutting off serves no purpose and hurts nothing. The reentrant corner is already there and that’s the danger point. By removing the dangling tit he allows the 2x4 to be inserted, which now does a better job of supporting the heel of the rafter, as long as the rafter bears tightly on the new 2x4 at the heel; and there is no over cutting at the current notch. The disadvantage is that this moves the rafter bearing further out on the clg. joist, instead of out over the bearing wall, and now this must be rationalized.

Sifu:

That whole roof framing effort is a botched-up mess, which shows that the guy really doesn’t understand what he is doing. He seems to have no concept of clean load paths or connection details; or why things are done the way they are normally done. Because of the messy details, every step of the way is a challenge to rationalize with the code or good sound design practice. You are right to make the builder’s engineer rationalize and explain all of these goofy details, just hand him the most complete list of problem areas that you can come up with. And, I would enforce that stop-order until he does his work and you have a meeting-of-the-minds.

What do you mean by ‘over-spanning rafters’? That the span length, roof load, or spacing are to great for the rafter size? You’ve not told us any of these, except the rafter size. Remember that roof DL has to be adjusted to a horiz. projection and then added to the LL to use the rafter tables, maybe the tables do already do this. Incomplete and complicated load paths are a real critical condition. The most direct connection btwn. the rafter and the clg. joist must transmit the rafter thrust into the clg. joist. Reread my other posts, I mentioned blocking btwn. the ceiling joists, or a rim joist, this is to prevent the joists from just rolling over, like a house of cards, just parallelograming onto the top plates. Otherwise, ICE offers a good starter list of things that need attention in that one photo.

The dangling tit that DRP suggests cutting off serves no purpose and hurts nothing. The reentrant corner is already there and that’s the danger point. By removing the dangling tit he allows the 2x4 to be inserted, which now does a better job of supporting the heel of the rafter, as long as the rafter bears tightly on the new 2x4 at the heel; and there is no over cutting at the current notch. The disadvantage is that this moves the rafter bearing further out on the clg. joist, instead of out over the bearing wall, and now this must be rationalized.

Sifu:

That whole roof framing effort is a botched-up mess, which shows that the guy really doesn’t understand what he is doing. He seems to have no concept of clean load paths or connection details; or why things are done the way they are normally done. Because of the messy details, every step of the way is a challenge to rationalize with the code or good sound design practice. You are right to make the builder’s engineer rationalize and explain all of these goofy details, just hand him the most complete list of problem areas that you can come up with. And, I would enforce that stop-order until he does his work and you have a meeting-of-the-minds.

What do you mean by ‘over-spanning rafters’? That the span length, roof load, or spacing are to great for the rafter size? You’ve not told us any of these, except the rafter size. Remember that roof DL has to be adjusted to a horiz. projection and then added to the LL to use the rafter tables, maybe the tables do already do this. Incomplete and complicated load paths are a real critical condition. The most direct connection btwn. the rafter and the clg. joist must transmit the rafter thrust into the clg. joist. Reread my other posts, I mentioned blocking btwn. the ceiling joists, or a rim joist, this is to prevent the joists from just rolling over, like a house of cards, just parallelograming onto the top plates. Otherwise, ICE offers a good starter list of things that need attention in that one photo.

Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,572

Going from memory here: He has a 2x8 rafter with a horizontal span of 20'2, the code span table indicates 17'11. If I take it straight out of the code he is over-spanned. The WFCM does indicate an increase of span multiplied by 1.07 for the 8/12 pitch. (I utilize the WFCM because I try to find ways to pass folks, not find ways to fail them) In this case he is still over-spanned, though by the WFCM the over-span is less. To be quite honest I don't typically use the increase in the WFCM because I'm not entirely sure I understand it. It may be legit but I don't like pulling little pieces of it out to justify something the code doesn't permit. The increase may be what you say about the span taking into consideration the adjustment but I don't know for sure. If the code intended that adjustment, it would be in there wouldn't it? BTW the WFCM shows the same allowable span as the code table. By my eyes he has an over-spanned rafter with a max notched or over notched condition, those two conditions together don't seem to be a good idea. Seems like he will have maximum load and deflection with minimum resistance at the heel joint to withstand the resulting force at the heel joint.dhengr said:What do you mean by ‘over-spanning rafters’? That the span length, roof load, or spacing are to great for the rafter size? You’ve not told us any of these, except the rafter size. Remember that roof DL has to be adjusted to a horiz. projection and then added to the LL to use the rafter tables, maybe the tables do already do this. Incomplete and complicated load paths are a real critical condition. The most direct connection btwn. the rafter and the clg. joist must transmit the rafter thrust into the clg. joist. Reread my other posts, I mentioned blocking btwn. the ceiling joists, or a rim joist, this is to prevent the joists from just rolling over, like a house of cards, just parallelograming onto the top plates. Otherwise, ICE offers a good starter list of things that need attention in that one photo.

Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,572

As far as the parrallelograming of the CJ to give it lateral stability I agree, I just need code to back it up. The way I read the code, it requires blocking for lateral stability if the member exceeds 6 to 1, which a 2x8 doesn't meet. Have I missed a code that says otherwise? I hate to beat a dead horse but if I don't have code, specifically IRC 2006, I have a tough road. I will get slapped down hard and fast by my BO if I go outside of it. I was told today that if I was going to require verification of things like individual member reports for LVL's or truss drawings that the BO was going to recommend dissolving the department to the county commision and that stuff is in the code!

So what you are looking for is what you might have enforced had you been able to enforce anything.

GBrackins

REGISTERED

I don't know if this will help or not, I don't know if much can help you in your situation except a change of venue ....Sifu said:As far as the parrallelograming of the CJ to give it lateral stability I agree, I just need code to back it up. The way I read the code, it requires blocking for lateral stability if the member exceeds 6 to 1, which a 2x8 doesn't meet. Have I missed a code that says otherwise? I hate to beat a dead horse but if I don't have code, specifically IRC 2006, I have a tough road. I will get slapped down hard and fast by my BO if I go outside of it. I was told today that if I was going to require verification of things like individual member reports for LVL's or truss drawings that the BO was going to recommend dissolving the department to the county commision and that stuff is in the code!

In Massachusetts we adopted the 2009 International Energy Conservation Code. When air permeable insulation is used with soffit vents the insulation must be sealed at the exterior wall to prevent wind-washing of the insulation. I use 2x blocking to aid in accomplishing this. Of course there are other methods that can be used to seal with, but blocking is met with less resistance from local builders. This way I get the blocking I want for the roof diaphragm and justify it by the energy code no matter the size of the rafter/ceiling joist.

Section 402.4 Air Leakage (Mandatory) #12 of 2009 IECC requires air sealing of other sources of air infiltration. See Section N1102.4 #10 of the 2006 IRC, requires sealing of other sources of air infiltration.

Sounds like you are fighting an uphill battle without any ammunition when it comes to your BO, especially if he slaps down requiring documentation of LVL's and trusses.

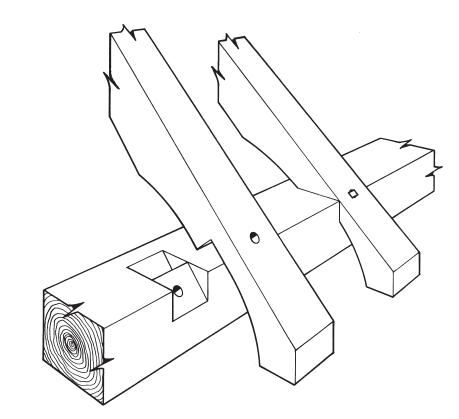

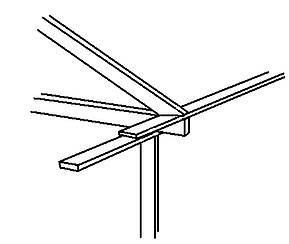

I remembered a pic I posted a few months ago. Here the step is fully supported and used to resist the horizontal thrust of the rafter. Not a notch in the code sense, the dangling tit is doing serious work, so much so that it is checked for crushing and shearing off of the relish beyond the notch in the bottom chord.

This is a step lapped rafter. The "notch" is the area removed by the gently curved cope on the underside. This predates the NDS by a couple of hundred years but the old carpenters understood the part where it says that it's a good idea to gently taper out of a notch rather than making them square cornered. The 90 degree "notch" is the rafter end bearing, is fully supported and locked in against thrust very well. It is not a "notch" in the sense of the code useage.

This is the document the above drawing came from, an excellent free download;

http://ncptt.nps.gov/pdf/2004-08.pdf

In my modification look in the document above at pg 10 fig 8, a raising plate.

This is a step lapped rafter. The "notch" is the area removed by the gently curved cope on the underside. This predates the NDS by a couple of hundred years but the old carpenters understood the part where it says that it's a good idea to gently taper out of a notch rather than making them square cornered. The 90 degree "notch" is the rafter end bearing, is fully supported and locked in against thrust very well. It is not a "notch" in the sense of the code useage.

This is the document the above drawing came from, an excellent free download;

http://ncptt.nps.gov/pdf/2004-08.pdf

In my modification look in the document above at pg 10 fig 8, a raising plate.

Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,572

Pretty cool way to install rafters. I can't even begin to imagine someone doing that today in standard light frame construction, though I imagine timber frames use something like it. After the discussion on the rafter notches I took a real close look at them and based on my new-found rafter notch education they were not as bad as originally thought. I had him pack them out in a few places where they might have been a little much as was shown and I had him add purlins everywhere to relieve the loads on the ends of the rafters. As for the OP, I issued corrections which included seeing a DP. I have not heard back since that last meeting which means he'll probably finish the house without making any corrections and call for a final.

globe trekker

REGISTERED

- Joined

- Oct 19, 2009

- Messages

- 1,739

Continuing to beat on this horse, I have read and re-read this topic &

discussion several times. Did Sifu ever get an actual answer to his

original question of: Is the rafter (in the pics.) overnotched,

according the letter of the code (max = 25%)?

Not saying that it is not a fixable situation, but is the rafter

overnotched by more than 25%? (RE: Section R802.7.1 in

the 2006 IRC)?

.

discussion several times. Did Sifu ever get an actual answer to his

original question of: Is the rafter (in the pics.) overnotched,

according the letter of the code (max = 25%)?

Not saying that it is not a fixable situation, but is the rafter

overnotched by more than 25%? (RE: Section R802.7.1 in

the 2006 IRC)?

.

It does not appear to be overnotched by code.

Code also allows a joist to be notched up to 25% of depth to sit on a ledger.

Notching like this in a material that is weak in tension perpendicular to grain is asking for trouble though.

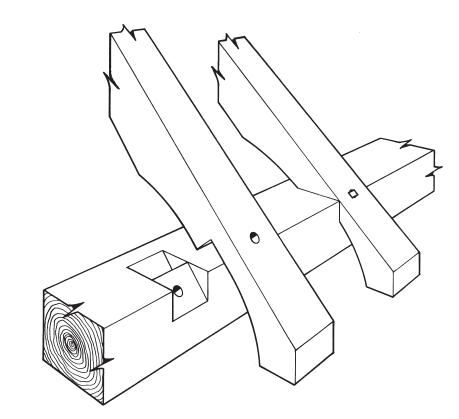

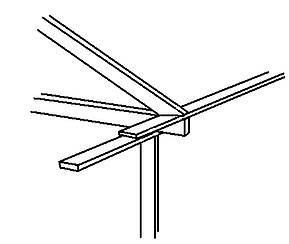

This is another sketch I had on photobucket.

It is an old roof framing method called a "raising plate". This is basically the repair I was suggesting. In this situation the load does move inboard in doing so and dhengr pointed that out. I'll counter that in this situation the load would not shift more than the depth of the joist and would then pass without review.

Code also allows a joist to be notched up to 25% of depth to sit on a ledger.

Notching like this in a material that is weak in tension perpendicular to grain is asking for trouble though.

This is another sketch I had on photobucket.

It is an old roof framing method called a "raising plate". This is basically the repair I was suggesting. In this situation the load does move inboard in doing so and dhengr pointed that out. I'll counter that in this situation the load would not shift more than the depth of the joist and would then pass without review.

globe trekker

REGISTERED

- Joined

- Oct 19, 2009

- Messages

- 1,739

Continuing on with my question, ..as an example, if a 2" x 6" is

used as a roofing rafter, and that rafter is cut (notched) more

than 1.375" ( 1 3/8" ), is it a violation of Section R802.7.1 in

the 2006 IRC? Also, suppose the a 2" x 6" rafter is notched at

1.50", 1.675", ? When does it become an actual violation of

Section R802.7.1? Yeah, I am a having difficult time with

this section and Section 2308.8.2 in the 2006 IBC.

.

used as a roofing rafter, and that rafter is cut (notched) more

than 1.375" ( 1 3/8" ), is it a violation of Section R802.7.1 in

the 2006 IRC? Also, suppose the a 2" x 6" rafter is notched at

1.50", 1.675", ? When does it become an actual violation of

Section R802.7.1? Yeah, I am a having difficult time with

this section and Section 2308.8.2 in the 2006 IBC.

.

The birdsmouth is not a notch in the sense of this section. Think of it as the end cut on a stud. However once the seat cut slides inboard off the top plate that bears its' tension edge, the underhanging section, measured perdendicular to grain, becomes the unsupported notch. If there is a tail extending beyond the wall, then you must leave at least a 2x4 section of wood remaining above the birdsmouth.

Look at my raising plate rafter, you've seen the same level cut on trusses, it goes all the way down to nothing. That is not a notch it is the end of the beam/column. The birdsmouth is the same, you're good till you slide the cut on the tension edge off the bearing.

Look at my raising plate rafter, you've seen the same level cut on trusses, it goes all the way down to nothing. That is not a notch it is the end of the beam/column. The birdsmouth is the same, you're good till you slide the cut on the tension edge off the bearing.

Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,572

I am glad I am not the only one that had trouble with this. I understand it better now, (I think) seeing the underhanging section as the notched portion where I was looking at the entire seat cut and/or vertical cut. I went back and looked long and hard at these rafters and all rafters since then. It makes better sense the way DRP explains now than it ever has.

globe trekker

REGISTERED

- Joined

- Oct 19, 2009

- Messages

- 1,739

Thanks DRP!

Forgive me for being slow of mind on this one. When Section R802.7.1,

Sawn Lumber (from the 2006 IRC), states that: Notches at the ends of the

member shall not exceed one fourth the depth of the member, I do not

understand how a birdsmouth is not a notch.

This particular section, and Section 2308.8.2 in the 2006 IBC, IMO, may

need some additional wording as clarification.

.

Forgive me for being slow of mind on this one. When Section R802.7.1,

Sawn Lumber (from the 2006 IRC), states that: Notches at the ends of the

member shall not exceed one fourth the depth of the member, I do not

understand how a birdsmouth is not a notch.

This particular section, and Section 2308.8.2 in the 2006 IBC, IMO, may

need some additional wording as clarification.

.

steveray

SAWHORSE

GT...the birdsmouth is only a notch once it exceeds the bearing point.....once it is past the point of bearing, it can be cut all the way through (crosscut) and considered a notch....if it is supported, the notch does not really matter...

dhengr

Bronze Member

The birds mouth on a rafter bearing, on a wall top plate, is not a notch in this discussion because of the way the stress act on the member at the point of what obviously looks like a notch to all of us. The eave overhand puts the member in compression at the reentrant corner of the notch, that is the effect of the overhang, a cantilever moment, and the shear stresses are fairly low. Thus, this notch does not have a tendency to split with (along) the grain, also the tension edge is on the top of the member at this location. The bearing surface of the birds mouth is supported by the top wall plate, in bearing or compression, so its likelihood of splitting along the grain is minimized. The birds mouth is o.k. as long as the horiz. seat cut is not longer than the width of the 2x4 or 2x6 wall top plate which supports it.

When the rafter has a long horiz. seat cut, so the tension edge of the rafter substantially overhangs the inter edge of the wall top plate, then the tension edge of the rafter is not supported and can split along the grain. If you extended the tension edge of the rafter to the wall, it might actually meet the wall below the wall top plates. This forms the notch DPR and I are talking about, and it is very likely more than 25% of the member depth, measured perpendicular to the lower edge of the rafter. The reentrant point of this notch is right at the upper/inner corner of the top plates, even if the seat cut is just a long horiz. cut. It is akin to a 2" notch at the bearing end of a 2x8 floor joist.

This type of notch is dangerous for several reasons. It is in the tension edge of the spanning member which is inherently dangerous, even though the bending stresses are very low at this location. The bigger problem at the member bearing has to do with shear stress, which is max. at the bearing or member reaction. Wood is notorious for splitting with (along) the grain of the member. Wood is actually quite strong w.r.t. a shear stress (shearing force, vert. reaction force) which tries to cleave it across the grain. But, at this notch point the vert. reaction force also produces what we call horiz. shear, equal in magnitude to the vert. shear stress, but acting along the grain, which tends to split the member with the grain. The horiz. shear stress is the killer at these notches, it is happening in a region of tensile stresses; and is maximized because it is acting on a smaller member at the bearing due to the notch. In my example above the 2" notch has effectively turned the 2x8 into a 2x6 which also means the shear stress effectively increases because of this loss in member area. Thus a shear stress of 135psi on the 2x8 becomes 180psi on the 2x6, a 33% shear stress increase, right at the notch.

On the other hand, the notch in the tension edge of a beam in the middle of its span is a killer because it interrupts the uniform (smooth) flow of the tensile stresses where they are at their max. It also reduces the depth of the member or its stiffness, and causes a reentrant corner which is prone to splitting along the grain. Although, in this area the shear stress is usually fairly low. So the notch at mid span is controlled by one set of stresses and conditions, while the notch at the beam bearing is controlled by another set of stresses and conditions.

When the rafter has a long horiz. seat cut, so the tension edge of the rafter substantially overhangs the inter edge of the wall top plate, then the tension edge of the rafter is not supported and can split along the grain. If you extended the tension edge of the rafter to the wall, it might actually meet the wall below the wall top plates. This forms the notch DPR and I are talking about, and it is very likely more than 25% of the member depth, measured perpendicular to the lower edge of the rafter. The reentrant point of this notch is right at the upper/inner corner of the top plates, even if the seat cut is just a long horiz. cut. It is akin to a 2" notch at the bearing end of a 2x8 floor joist.

This type of notch is dangerous for several reasons. It is in the tension edge of the spanning member which is inherently dangerous, even though the bending stresses are very low at this location. The bigger problem at the member bearing has to do with shear stress, which is max. at the bearing or member reaction. Wood is notorious for splitting with (along) the grain of the member. Wood is actually quite strong w.r.t. a shear stress (shearing force, vert. reaction force) which tries to cleave it across the grain. But, at this notch point the vert. reaction force also produces what we call horiz. shear, equal in magnitude to the vert. shear stress, but acting along the grain, which tends to split the member with the grain. The horiz. shear stress is the killer at these notches, it is happening in a region of tensile stresses; and is maximized because it is acting on a smaller member at the bearing due to the notch. In my example above the 2" notch has effectively turned the 2x8 into a 2x6 which also means the shear stress effectively increases because of this loss in member area. Thus a shear stress of 135psi on the 2x8 becomes 180psi on the 2x6, a 33% shear stress increase, right at the notch.

On the other hand, the notch in the tension edge of a beam in the middle of its span is a killer because it interrupts the uniform (smooth) flow of the tensile stresses where they are at their max. It also reduces the depth of the member or its stiffness, and causes a reentrant corner which is prone to splitting along the grain. Although, in this area the shear stress is usually fairly low. So the notch at mid span is controlled by one set of stresses and conditions, while the notch at the beam bearing is controlled by another set of stresses and conditions.

globe trekker

REGISTERED

- Joined

- Oct 19, 2009

- Messages

- 1,739

Thanks to all for your input!

I came across the following link in my search for some

more information on notches, birdsmouth cuts, rafters,

and etc. Check it out!

http://www.builderbill-diy-help.com/rafter-cuts.html

Hope this helps!

.

I came across the following link in my search for some

more information on notches, birdsmouth cuts, rafters,

and etc. Check it out!

http://www.builderbill-diy-help.com/rafter-cuts.html

Hope this helps!

.