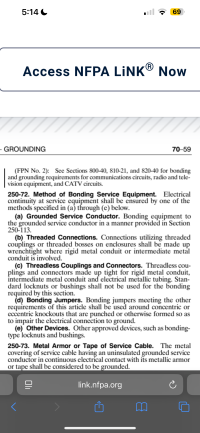

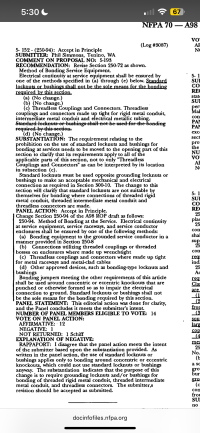

Is it necessary to size a bonding jumper to 250.122 if the only purpose of the bonding jumper is to connect to the bonding bushing on a metal raceway for a service? No concentric knockouts or impaired connection, the only purpose is to comply with the section that states "Standard locknuts or bushings shall not be the only means for bonding required by this section".

The only reason I am wondering is that the metal raceway "is" bonded by standard locknuts etc. and the bonding jumper is added on services to make a lower impedance connection so that you can pull enough amps to blow the fuses on the primary side of the utility transformer, which can take 2-4 times the amount of current that your main breaker would require.

This photo is an example from my old photos to demonstrate basically what I am talking about, but not a current install and may not fit my question entirely.

The only reason I am wondering is that the metal raceway "is" bonded by standard locknuts etc. and the bonding jumper is added on services to make a lower impedance connection so that you can pull enough amps to blow the fuses on the primary side of the utility transformer, which can take 2-4 times the amount of current that your main breaker would require.

This photo is an example from my old photos to demonstrate basically what I am talking about, but not a current install and may not fit my question entirely.