jar546

CBO

Let's make this simple. We can look at a typical 3HP 115/230v motor that will be used for continuous duty and will be the only motor on a circuit. It is not a DC motor, nor is it a multi-speed motor, or a Wye-Start/Delta Run Motor or a Part-Winding Motor or even anything other than a continuous duty motor. A typical, everyday motor. Nice and easy to follow. The questions are:

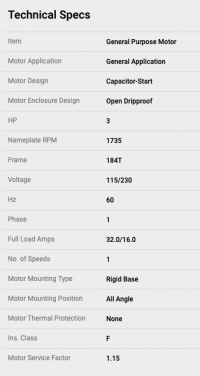

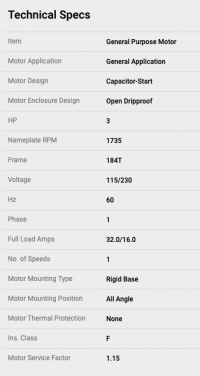

What size copper wire do we need and what size overload & overcurrent protection. We can look at both of those separately but first, here is the info that will be on the nameplate:

First let's look at conductor (wire) size. Part II of NEC 430 is Motor Circuit Conductors and for a single motor as described 430.22 tells us that conductors that supply a single motor used in a continuous duty application shall have an ampacity of not less than 125% of the motor full-load current rating as determined by 430.6(A)(1).

Full-Load Current, otherwise know as FLC is found on in the NEC tables. Remember, 430.6(A)(1) lets us know that in order to find the amperage for the conductors, we use the charts and not the label of the motor which normally only gives the FLA. For this example, we will be using the charts and assuming the 3 exceptions to not apply.

NEC 430.6(A)(1) sends us to Tables 430.247, 430.248, 430.249 & 430.250. Let's go take a look.

Our motor is clearly labeled as 3HP and we will be wiring this with 230v from a double-pole breaker so we will be using 430.248 which gives us 17A. Looking at Table 310.15(B)(16) we see that we will need a 12awg wire for the conductors.

We now have to figure out what size overload protection we need so let's head over to Part III, NEC 430.32(A) Continuous Duty Motors. This motor is greater than 1HP and per the nameplate, does not have any integral Motor Thermal Protection. Overload protection is to protect against an overheating motor which can be from various reasons from startup to a locked rotor. It is NOT for short circuit.

OK we are now know we have to use 430.32(A)(1) a separate overload device such as fuses or an overload device used in conjunction with a contactor as two examples. We use the data plate, specifically the Full Load Amps (FLA) and Motor Service Factor to determine the overload protection. Here we see that the service factor is 1.15 and the full load amps for 230V is 16.0. We now have to multiply 16A x 125% per 430.32(A)(1) for an overload protection of 20A. We will need 20A fuses for overload protection.

Lastly we have to worry about a short circuit, ground-fault, etc. which is how we decide our circuit breaker size. Part IV of NEC 430 covers this starting with 430.51 which states that the purpose of this section is to protect the conductors, motor controls and motors against overcurrent due to short circuits or ground faults.

430.52 applies to us as we are using this for an individual motor circuit. Within this section we are directed to Table 430.52 which has us use the Full Load Current (FLC) again and NOT the nameplate of the motor. Our FLC as determined by the NEC was 17A. Remember we found that in Table 430.248. We will be using an Inverse Time Breaker (typical of panelboards) for this single-phase motor which gives us 250% of FLC. Therefore, 17A x 250% would be 42.5A and since we are allowed, we would use a 45A breaker.

So this motor circuit will have 12awg wire with 20A OL protection and fed from a 45A breaker which is the next standard size above 40A. Now you see it is possible to legally have a 12awg wire connected to a 45A breaker.

There are a ton of other variables that could have affected these numbers but keeping is simply, typical and straight forward, I believe, is the best approach. You can branch out from here.

I hope this helps and provides useful information for the forum.

What size copper wire do we need and what size overload & overcurrent protection. We can look at both of those separately but first, here is the info that will be on the nameplate:

First let's look at conductor (wire) size. Part II of NEC 430 is Motor Circuit Conductors and for a single motor as described 430.22 tells us that conductors that supply a single motor used in a continuous duty application shall have an ampacity of not less than 125% of the motor full-load current rating as determined by 430.6(A)(1).

Full-Load Current, otherwise know as FLC is found on in the NEC tables. Remember, 430.6(A)(1) lets us know that in order to find the amperage for the conductors, we use the charts and not the label of the motor which normally only gives the FLA. For this example, we will be using the charts and assuming the 3 exceptions to not apply.

NEC 430.6(A)(1) sends us to Tables 430.247, 430.248, 430.249 & 430.250. Let's go take a look.

Our motor is clearly labeled as 3HP and we will be wiring this with 230v from a double-pole breaker so we will be using 430.248 which gives us 17A. Looking at Table 310.15(B)(16) we see that we will need a 12awg wire for the conductors.

We now have to figure out what size overload protection we need so let's head over to Part III, NEC 430.32(A) Continuous Duty Motors. This motor is greater than 1HP and per the nameplate, does not have any integral Motor Thermal Protection. Overload protection is to protect against an overheating motor which can be from various reasons from startup to a locked rotor. It is NOT for short circuit.

OK we are now know we have to use 430.32(A)(1) a separate overload device such as fuses or an overload device used in conjunction with a contactor as two examples. We use the data plate, specifically the Full Load Amps (FLA) and Motor Service Factor to determine the overload protection. Here we see that the service factor is 1.15 and the full load amps for 230V is 16.0. We now have to multiply 16A x 125% per 430.32(A)(1) for an overload protection of 20A. We will need 20A fuses for overload protection.

Lastly we have to worry about a short circuit, ground-fault, etc. which is how we decide our circuit breaker size. Part IV of NEC 430 covers this starting with 430.51 which states that the purpose of this section is to protect the conductors, motor controls and motors against overcurrent due to short circuits or ground faults.

430.52 applies to us as we are using this for an individual motor circuit. Within this section we are directed to Table 430.52 which has us use the Full Load Current (FLC) again and NOT the nameplate of the motor. Our FLC as determined by the NEC was 17A. Remember we found that in Table 430.248. We will be using an Inverse Time Breaker (typical of panelboards) for this single-phase motor which gives us 250% of FLC. Therefore, 17A x 250% would be 42.5A and since we are allowed, we would use a 45A breaker.

So this motor circuit will have 12awg wire with 20A OL protection and fed from a 45A breaker which is the next standard size above 40A. Now you see it is possible to legally have a 12awg wire connected to a 45A breaker.

There are a ton of other variables that could have affected these numbers but keeping is simply, typical and straight forward, I believe, is the best approach. You can branch out from here.

I hope this helps and provides useful information for the forum.