-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So This Part of the House is Going to be Interesting

- Thread starter jar546

- Start date

jar546

CBO

jar546

CBO

Msradell

SAWHORSE

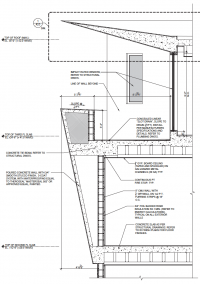

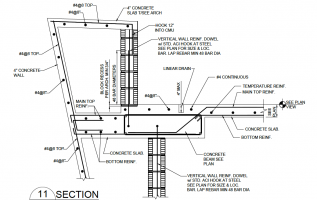

That detail for the 3rd floor is interesting, I would think they would have connected the rebar in the top face to the front face. By not doing that you have a much higher possibility of separation between the 2 surfaces. You have the same thing and the roof projection but at least that is sound concrete which greatly reduces the problem.

Yankee Chronicler

SAWHORSE

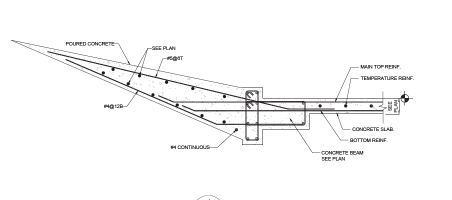

I'll give it ten years before the tips of the roof overhang start to break off.

I’ll give it until they attempt to remove the forms.I'll give it ten years before the tips of the roof overhang start to break off.

jar546

CBO

Especially since this house is right on the ocean in south Florida with hot, humid air coming in. This will be interesting.I'll give it ten years before the tips of the roof overhang start to break off.

MtnArch

SAWHORSE

But it looks so cool on paper ...

mtlogcabin

SAWHORSE

MtnArch

SAWHORSE

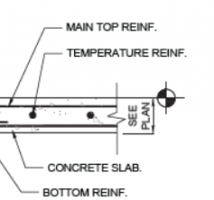

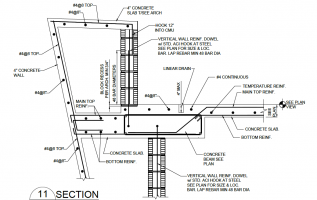

Radiant floor tubing?Please explain what "temperature" reinforcement is. In 30 years I have never seen a set of plans that used that term for reinforcement.

View attachment 13549

wwhitney

REGISTERED

Reinforcement against stresses induced by expansion/contraction due to temperature changes. I gather the excerpt is for a roof slab, so the temperature variation on the upper surface of it will be greater a slab would see from earth contact or from exposure to conditioned space.Please explain what "temperature" reinforcement is. In 30 years I have never seen a set of plans that used that term for reinforcement.

My understanding is that typically the reinforcement required for flexure will be greater that the required temperature/shrinkage reinforcement, so plans would typically call out just the flexure reinforcement. But if the slab is designed for bending along only one axis, in the perpendicular direction, temperature/shrinkage may control the amount of reinforcement required.

Cheers, Wayne

Paul Sweet

SAWHORSE

Building the formwork is going to be very interesting.

steveray

SAWHORSE

Si........Building the formwork is going to be very interesting.

Msradell

SAWHORSE

Temperature/shrinkage reinforcement refers to the reinforcing bars placed in a direction perpendicular to the main bars that resist flexure. The purpose of the temperature/ shrinkage bars is to limit the width of cracks that are caused by stresses due to temperature changes and shrinkage of concrete.

brokenkeys

Member

The craziest part about these super-high end houses is the owner will live in the house maybe a few days a year then sell it within a few years. Absolutely bonkers.

The first thing that jumped out at me is they misspelled Thoroseal. Not that it matters since they sold out to Sika long ago. Makes me wonder how much of the rest is copy pasta.

Speaking of pasta; I hope they planned out the crack control well.

The first thing that jumped out at me is they misspelled Thoroseal. Not that it matters since they sold out to Sika long ago. Makes me wonder how much of the rest is copy pasta.

Speaking of pasta; I hope they planned out the crack control well.

Yankee Chronicler

SAWHORSE

I think it's curious that the slanted concrete wall is only 4 inches thick. The rebars are #4 (1/2") in each direction, so that's a total of one inch. Assuming that the rebar should have a minimum of 1-1/2" of cover, that leaves essentially zero leeway for where in the wall the steel gets placed. That means the vertical bars' axis will be located just 1/4-inch off the neutral axis of the slanted wall. That's almost a "Why even bother?" situation.

wwhitney

REGISTERED

I think you mean 1/4" off the center of the slanted wall. As a composite material, the neutral axis in bending may not lie at the center of the cross section.I think it's curious that the slanted concrete wall is only 4 inches thick. The rebars are #4 (1/2") in each direction, so that's a total of one inch. Assuming that the rebar should have a minimum of 1-1/2" of cover, that leaves essentially zero leeway for where in the wall the steel gets placed. That means the vertical bars' axis will be located just 1/4-inch off the neutral axis of the slanted wall.

Cheers, Wayne

Yankee Chronicler

SAWHORSE

I think you mean 1/4" off the center of the slanted wall. As a composite material, the neutral axis in bending may not lie at the center of the cross section.

Cheers, Wayne

Correct. But with the longitudinal steel so close to the centerline of the wall, the neutral axis can't be very far from the centerline.

wwhitney

REGISTERED

That makes sense for low flexural demand where the concrete is uncracked and can act in tension. As then the cross-section is almost symmetric.Correct. But with the longitudinal steel so close to the centerline of the wall, the neutral axis can't be very far from the centerline.

But for higher flexural demands, the cross section has an effective depth of 2-1/4" (if the steel is placed precisely), the distance from the compressive face to the center of the tensile steel. And the neutral axis is going to end up somewhere near the middle of that. I calculated with low confidence (as I'm not an engineer and have not done the calculations before, and didn't look up the appropriate ACI sections or check if there are limits on applying the procedure to such a shallow member), for an 8" wide member with one #4 bar, 3000 psi concrete, and 60 ksi steel, the neutral axis at flexural capacity will end up at 0.68" from the compressive face, or 1.32" off-center in the 4" wall.

Cheers, Wayne