from '06 IRC:

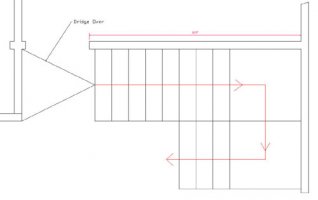

Winder treads shall have a minimum tread depth of 10 inches (254 mm) measured as above at a point 12 inches (305 mm) from the side where the treads are narrower.Winder treads shall have a minimum tread depth of 6 inches (152 mm) at any point. Within any flight of stairs, the largest winder tread depth

at the 12 inch (305 mm) walk line shall not exceed the smallest by more than 3/8 inch (9.5 mm).

Winder treads shall have a minimum tread depth of 10 inches (254 mm) measured as above at a point 12 inches (305 mm) from the side where the treads are narrower.Winder treads shall have a minimum tread depth of 6 inches (152 mm) at any point. Within any flight of stairs, the largest winder tread depth

at the 12 inch (305 mm) walk line shall not exceed the smallest by more than 3/8 inch (9.5 mm).