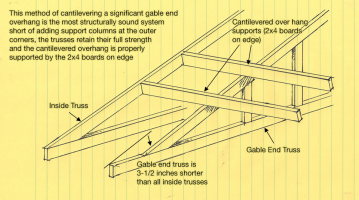

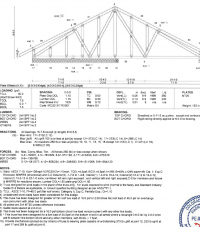

Most of the verticals in the gable truss drawings I looked at considered a load of less than 250lbs at each vertical. I think this is probably a calculation based on the overhand designed into the truss and the tributary load from 1/2 of the truss spacing. IMHO, these trusses are bearing. Does that mean that prescriptively we are going to require a built up header? Typically not for me. And even if I wanted to, there doesn't appear to be a table for trusses bearing parallel to the building width. (Never really liked these tables, but they are what we have). In the OP, it sounds like the inspector and/or the boss didn't have a clear understanding of this, and then everyone dug their heels in. If there are truss design drawings I think the issue could be resolved rather quickly...if personal feelings and opinions can be put aside. My comment was based on the contention that they are typically non-bearing. Some trusses require continuous bearing ( for various reasons as others have noted), some have concentrated loads.

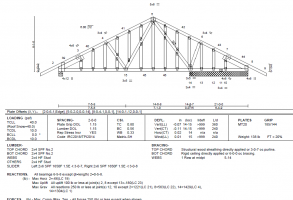

In the 1st drawing, the hatched bottom chord indicates a requirement for continuous bottom chord bearing, which is verified by note 7.

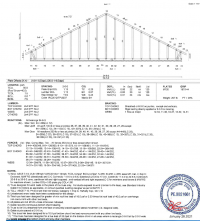

In the second drawing, even thought the truss looks to be symmetrical, one side is clearly non-bearing, but the other is bearing. And, in fact, joint 12 has considerably more reaction than the similar joint 9, which has no bearing requirement.

I am not an engineer so maybe my understanding of these drawings is wrong. When I inspected I required the layouts and shops on site. Even though I typically considered a standard gable truss as "non-bearing", I would look for the hatch, and if I saw it I would consider why.

View attachment 8245

View attachment 8246