I think what scares me most is imagining what that serves. My mind is filling in the rest of the picture, it isn't pretty.

-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

Yikes

SAWHORSE

Should have used TR outlets, right?

Someone told me a long time ago that water and electricity doesn't mix?

They may have proved that wrong?

In the 1960's my father had a project which utilized copper conductors that were pipe. Water flowed through the pipe to prevent it from melting.Someone told me a long time ago that water and electricity doesn't mix?

Grok said:

"Pure H₂O, in its ideal form, does not conduct electricity effectively because it contains no free ions or charged particles to carry an electric current. Water molecules are neutral, with a covalent bond between hydrogen and oxygen, and pure water has a very low concentration of ions due to minimal self-ionization (H₂O ⇌ H₃O⁺ + OH⁻). This self-ionization produces an extremely small number of ions (about 10⁻⁷ M at 25°C), resulting in very high electrical resistance.However, in practice, even "pure" water may contain trace impurities, dissolved gases (like CO₂, which can form carbonic acid), or ions from containers, which can slightly increase conductivity. For significant conduction, water typically needs dissolved electrolytes, like salts, to provide free ions.So, theoretically, pure H₂O is a poor conductor, but real-world "pure" water may conduct slightly due to impurities or self-ionization."

Where' the bonding?

Commercial job, new small restaurant. I was there for the plumbing rough. No one was there but the plumber. I was leaning on the ZIP wall talking to the plumber and noticed the fastener quantity and type. 99% of building was fastened this way. I wondered aloud if they were planning to come back to roll the ZIP tape and nail the panels off with a 6/12 nailing pattern per normal for shear. The plumber said they were planning to install siding the next day. We had not been called to look at the nail pattern, and this was at 4:00 in the afternoon.

Phone calls were made. The general contractor had not followed up on the subs that installed the ZIP and from the conversation I doubt that they would have before the siding went up. The siding installation was delayed pending a passing nailing inspection. The GC was from out of town, but had hired local subs that they didn't know had no business doing what they were doing. The GC was very cooperative and gave us no trouble. I do not think they will use those subs again.

Phone calls were made. The general contractor had not followed up on the subs that installed the ZIP and from the conversation I doubt that they would have before the siding went up. The siding installation was delayed pending a passing nailing inspection. The GC was from out of town, but had hired local subs that they didn't know had no business doing what they were doing. The GC was very cooperative and gave us no trouble. I do not think they will use those subs again.

Inspector Gadget

SAWHORSE

I was instrumental in having a contractor unhired recently.

Drove by a project - tight on time to go somewhere else. At 50km (30 mph for you in the Excited States), I saw an ICF foundation with vertical rebar way far apart. Shot an email to the client, who countered that his contractor said it was OK.

I sent the requirements to the client.

Then the client calls back and says the contractor wants to go above-grade in an earthquake zone, which requires special reinforcing. I told the client that special reinforcing was required.

"The contractor says he doesn't need to."

So I send the contractor a few bits of info that yes, he kinda does.

Client emailed back "Mr. Contractor is no longer working for me."

Drove by a project - tight on time to go somewhere else. At 50km (30 mph for you in the Excited States), I saw an ICF foundation with vertical rebar way far apart. Shot an email to the client, who countered that his contractor said it was OK.

I sent the requirements to the client.

Then the client calls back and says the contractor wants to go above-grade in an earthquake zone, which requires special reinforcing. I told the client that special reinforcing was required.

"The contractor says he doesn't need to."

So I send the contractor a few bits of info that yes, he kinda does.

Client emailed back "Mr. Contractor is no longer working for me."

So you’re one of those infamous drive-by inspectors … ?Drove by a project - tight on time to go somewhere else. At 50km (30 mph for you in the Excited States), I saw an ICF foundation with vertical rebar way far apart.

Inspector Gadget

SAWHORSE

In this case, yes. Had three minutes to get to a ferry.So you’re one of those infamous drive-by inspectors … ?

I was poking fun, hope i didn’t offend you. Must be difficult to work around ferry schedules.In this case, yes. Had three minutes to get to a ferry.

Inspector Gadget

SAWHORSE

I have a thick skin, and a sense of humour; but I figured it was worth explaining nonetheless.I was poking fun, hope i didn’t offend you. Must be difficult to work around ferry schedules.

LOL I just couldn't let that go.I was poking fun, hope i didn’t offend you. Must be difficult to work around fairy schedules.

Damn homophones.LOL I just couldn't let that go.

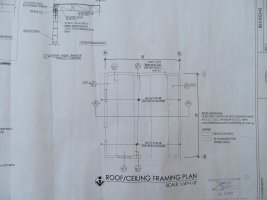

I was searching for a picture related to headers when I came across this. The hardware and blocking was installed because the roof plan called for boundary nailing of every edge of the sheathing. The steel angles are at a minimum 3/8" and might be 1/2". It has been too long ago for me to remember the exact details. I was concerned about the added weight. Imagine what that cost.

Looks like the ahj insisted on that after several go-arounds, and the contractor said “you want angle braces and bolts? I’ll show you braces!”I was searching for a picture related to headers when I came across this. The hardware and blocking was installed because the roof plan called for boundary nailing of every edge of the sheathing. The steel angles are at a minimum 3/8" and might be 1/2". It has been too long ago for me to remember the exact details. I was concerned about the added weight. Imagine what that cost.

View attachment 16268

View attachment 16269

CORRECTION:The hardware and blocking was installed because the roof plan called for boundary nailing of every edge of the sheathing.

I was completely wrong. I found another batch of pictures with the truth of the matter. My excuse is that it happened in 2017 which is around 20,000 inspections ago,

As it turns out, there was a wacky engineer on the job.

Last edited:

steveray

SAWHORSE

yep...Nice that the wood was preasssured to work...What more do you need?CORRECTION:

I was completely wrong. I found another batch of pictures with the truth of the matter. My excuse is that it happened in 2017 which is around 20,000 inspections ago,

As it turns out, there was a wacky engineer on the job.

View attachment 16291

View attachment 16292