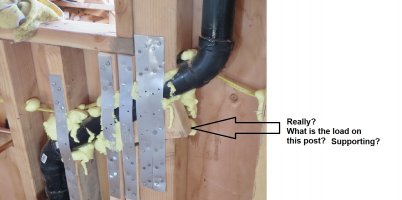

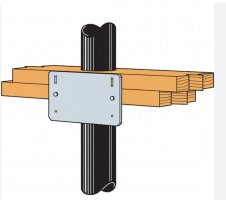

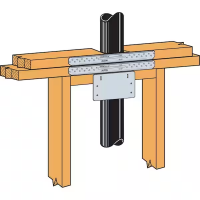

312.9 Steel Nail Plates. Plastic and copper piping penetrating framing members to within 1 inch of the exposed framing shall be protected by steel nail plates not less than No. 18 gauge in thickness. The steel nail plate shall extend along the framing member not less than 1-1⁄2 inches beyond the outside diameter of the pipe or tubing.

On a recent inspection I noted that the nail plates did not extend 1-1/2" beyond the pipe. This was a tract inspection and the superintendent said that the usual inspector had told him about that but the city wasn't enforcing that code because there was a question if the plate was required to stick up in the attic space. So they assumed that the 1-1/2" was on the vertical and not the horizontal. I pointed out that the code says. The steel nail plate shall extend along the framing member"

My take on it is that the plate shall extend horizontally however, I have encountered the vertical interpretation many times.

I do have a question. "not less than 1-1⁄2 inches beyond the outside diameter of the pipe or tubing." I have understood that to mean that the plate shall extend 1-1/2" past each side of a pipe. For example a 3" pipe would require no less than a 6-1/2" plate. Some have decided that the plate only needs to be 1-1/2" larger than the OD of the pipe.

What say you?

On a recent inspection I noted that the nail plates did not extend 1-1/2" beyond the pipe. This was a tract inspection and the superintendent said that the usual inspector had told him about that but the city wasn't enforcing that code because there was a question if the plate was required to stick up in the attic space. So they assumed that the 1-1/2" was on the vertical and not the horizontal. I pointed out that the code says. The steel nail plate shall extend along the framing member"

My take on it is that the plate shall extend horizontally however, I have encountered the vertical interpretation many times.

I do have a question. "not less than 1-1⁄2 inches beyond the outside diameter of the pipe or tubing." I have understood that to mean that the plate shall extend 1-1/2" past each side of a pipe. For example a 3" pipe would require no less than a 6-1/2" plate. Some have decided that the plate only needs to be 1-1/2" larger than the OD of the pipe.

What say you?

Last edited: