-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wall Bracing Revisited

- Thread starter jar546

- Start date

jar546

CBO

And the engineer says.....

TheCommish

SAWHORSE

engineer designs sheathing for ceiling with hold downs

RJJ

Co-Founder

No this is not ok! Portal framing is not done correctly. Can't see nail pattern on plywood or how it is fasten to the block. The guy picking his nose must be in charge!

JCraver

REGISTERED

Who put that cabinet smack in the middle of the driveway, and/or who picked that spot for the garage? I'm much more worried about that than I am the framing.

Some hurricane clips and a couple anchor bolts and that garage will stand there forever - much longer than it'll be before someone runs in to that cabinet.

Some hurricane clips and a couple anchor bolts and that garage will stand there forever - much longer than it'll be before someone runs in to that cabinet.

RJJ

Co-Founder

LOL! That cabinet is just a temporary obstruction!

Keystone

SAWHORSE

Can't tell you how often I run into this! The "A" typical engineer repair I receive, sheath interior portal wall.

RJJ

Co-Founder

But the portal framing starts at the foundation.

JCraver

REGISTERED

So maybe I'm missing something here and you all can educate me-

99.9% of buildings in my jurisdiction are built with this continuous sheathing method. So according to (2015) R602.10.6.4, and the Table and Figure that go with it, all this guy needs to do is add clips at the trusses, header-to-jack stud straps, and anchor bolts at the sill plate, and then as long as he uses enough nails in the sheathing then it meets the code. Is that not correct?

99.9% of buildings in my jurisdiction are built with this continuous sheathing method. So according to (2015) R602.10.6.4, and the Table and Figure that go with it, all this guy needs to do is add clips at the trusses, header-to-jack stud straps, and anchor bolts at the sill plate, and then as long as he uses enough nails in the sheathing then it meets the code. Is that not correct?

ADAguy

REGISTERED

Don't they use "Simpson"'s back there? Headers only toenailed?

mark handler

SAWHORSE

RJJ

Co-Founder

JCarver: yes that is correct. Also a few bollards to protect the cabinet.

my250r11

SAWHORSE

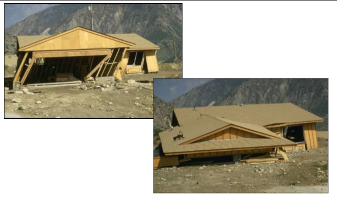

View attachment 3024

It will be Just Fine

To be fair they hadn't finished sheeting it yet. lol

Last edited:

mark handler

SAWHORSE

It wont matter If not done correctly

Not framed correctly

Not framed correctly

ADAguy

REGISTERED

Nice photos MH, thanks

JBI

REGISTERED

Does not meet the prescriptive provisions of the IRC.

We can start with the header termination relative to the framing cavity...

The prescriptive narrow panels require the header to continue to the last full height stud in order to lock the header to the framing cavity and add rigidity to the assembly.

Beyond that would need close up shots of the remaining details of construction to determine whatever else fails to meet prescriptive compliance.

An RDP will need to provide alternatives in accordance with accepted engineering practice (probably a bit more than a few hurricane clips and ceiling sheathing...)

We can start with the header termination relative to the framing cavity...

The prescriptive narrow panels require the header to continue to the last full height stud in order to lock the header to the framing cavity and add rigidity to the assembly.

Beyond that would need close up shots of the remaining details of construction to determine whatever else fails to meet prescriptive compliance.

An RDP will need to provide alternatives in accordance with accepted engineering practice (probably a bit more than a few hurricane clips and ceiling sheathing...)

tmurray

SAWHORSE

Interesting. This would be acceptable here, but we are in a low wind and earthquake zone.

ADAguy

REGISTERED

Yes, and also in another country (smiling).

mark handler

SAWHORSE

Header attachment, bearing.....Does not meet the prescriptive provisions of the IRC.

We can start with the header termination relative to the framing cavity...

The prescriptive narrow panels require the header to continue to the last full height stud in order to lock the header to the framing cavity and add rigidity to the assembly.

Beyond that would need close up shots of the remaining details of construction to determine whatever else fails to meet prescriptive compliance.

An RDP will need to provide alternatives in accordance with accepted engineering practice (probably a bit more than a few hurricane clips and ceiling sheathing...)