A product called Low-E Therma Sheet has been in the marketplace for several years. It has an ICC ESR #3652 as an underlayment

https://www.icc-es.org/wp-content/uploads/report-directory/ESR-3652.pdf

The following came from the ESR:

ESP Low-E® Therma-Sheet 4LMPX 1/8 inch and ESP Low-E® Therma-Sheet 4LFPX 7/32 inch roofing underlayments are used as alternatives to the ASTM D226, Type I and Type II, roofing underlayments specified in IBC Chapter 15 and IRC Chapter 9.

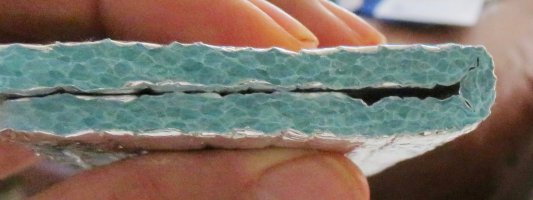

3.2 ESP Low-E® Therma-Sheet 4LFPX 7/32 inch: consists of a 7/32-inch-thick (5.6 mm)

polyethylene core with a 5 x 5 scrim-reinforced aluminum foil top surface and a 2 x 2

Minimum roof slope is 2:12 (17 percent). For roof slopes from 2:12 (17 percent) up to but not including 4:12 (33 percent), where the roof is covered with asphalt shingles, underlayment

must be two layers and must be applied in accordance with IBC Section 1507.2.8, 2015 IRC Sections R905.1.1 and R905.2.3 [2012 IRC Section R905.2.7]. As an alternative, when the roof is covered with asphalt shingles, one layer of ESP Low-E® Therma-Sheet underlayment and one layer of underlayment conforming to either ASTM D226, Type I, ASTM D4869, Type I or ASTM D6757 may be installed in accordance with IBC Section 1507.2.8, 2015 IRC Sections R905.1.1 and R905.2.3

Beginning at the lower edge of the roof, the first course of underlayment must be laid horizontally (parallel to the eave),

with 4-inch (102 mm) horizontal and 6-inch (152 mm) vertical laps.

5.5 Installation is limited to roofs with ventilated attic spaces.

5.6 Installation is limited to use with nonclassified roof coverings or as a component of a classified roofing assembly when specifically recognized as such in a listing approved by the code official.

Well there you have it

. The material is a legitimate underlayment for use with asphalt shingles.....even at two layers.

View attachment 5741

View attachment 5742

Squeezing it produces a sound like popping bubble wrap. It is foam. A 7/16" thick layer of polyethylene foam under an asphalt shingle seems wrong. I contacted ICC with questions. I was informed that ICC tested and approved the material as an underlayment. That none of the shingle manufacturers objected. That there have been no reports of any problems with the use. That it is not a "radiant barrier".

I contacted Malarkey, GAF, and Owens Corning. GAF technical service dept. stated that the LOW-E is not allowed under GAF shingles. Malarkey said no. Owens Corning said that the use of LOW-E underlayment will not void the warranty.

I found the material on a roof with GAF shingles:

View attachment 5743

I wrote a correction stating that GAF will not allow this. The contractor had a GAF representative call and email an approval for the use of LOW-E Therma Sheet underlayment and as usual "It will not void the warranty."

My department has told me that we can not disallow the use. I was told to check roofs at final (looking for nails that tore through the shingle). That's from a person sitting at a desk. I try to avoid walking on new shingles much less damaging tabs looking for damage.

"