Still goes back to the design of that panel leaving no other option but stuff a bunch of cables into a larger Romex® connector.I do not believe they need to be derated because they are not bundled for more than 24". However, the clamp is not listed for that many conductors, and is thusly a violation. I have written it up, but the only possible hazard I see is the cables rubbing on the exposed screw threads.

-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

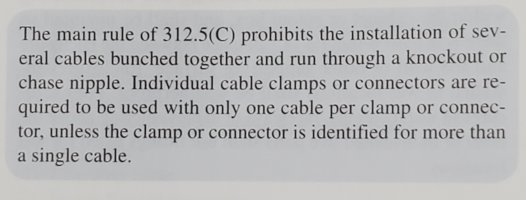

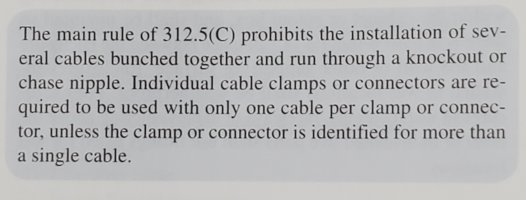

312.5(C) Cables.

Where cable is used, each cable shall be secured to the cabinet, cutout box, or meter socket enclosure.

This is from the handbook:

This is something that every electrician should learn early in their career. If they learn it from me it’s a bitter pill to swallow. I am okay with that. The rub is that it can be such a bitch to fix. The workman wants to hear from me why fifteen cables in a clamp is a safety issue worth the grief. I hear, “Can you let it goe this time?” If I let it go this time why would the correction have any merit next time….and there will be a next time.

Where cable is used, each cable shall be secured to the cabinet, cutout box, or meter socket enclosure.

This is from the handbook:

This is something that every electrician should learn early in their career. If they learn it from me it’s a bitter pill to swallow. I am okay with that. The rub is that it can be such a bitch to fix. The workman wants to hear from me why fifteen cables in a clamp is a safety issue worth the grief. I hear, “Can you let it goe this time?” If I let it go this time why would the correction have any merit next time….and there will be a next time.

Last edited:

steveray

SAWHORSE

Is it a cabinet? Or just a panelboard? We don't get a whole lot of cabinets in houses here...Unless they are not metal...

The paneboard is in a cabinet…cutout box..Is it a cabinet? Or just a panelboard? We don't get a whole lot of cabinets in houses here...Unless they are not metal...

UL has the following definition (UL White Book CYIV):

This category covers sheet-metal boxes and nonmetallic boxes. Cutout boxes are provided with a door secured by hinges and one or more fasteners and are intended for surface mounting. A cabinet consists of two parts:

a cabinet box and a mating cabinet front that contains a door. A cabinet may be flush mounted or surface mounted. These boxes are intended for installation in accordance with Article 312 of ANSI/NFPA 70, ‘‘National Electrical Code.’’

Last edited:

Commentary from the handbook is not enforceable, & there still is no way to do what you are saying with a large number of cables, there is physically not enough room to have individual Romex® connectors. Might be time to ban that style of panel.

The handbook is someone's opinion of what is enforceable. There's two ends to the cabinet and both ends provide KOs. On top, or bottom, of that is the use of a Greenlee punch.Commentary from the handbook is not enforceable, & there still is no way to do what you are saying with a large number of cables, there is physically not enough room to have individual Romex® connectors. Might be time to ban that style of panel.

If that cabinet won't work....oh well....try another.

north star

MODERATOR

- Joined

- Oct 19, 2009

- Messages

- 4,596

# ~ # ~ #

The whole idea of convenience to the contractors is

more valued than Code compliance, seems to be the

politically & culturally correct norms.........Enforcement

of the legally adopted Codes & Standards, for some,

...seems to be in theory only.

Hammurabi had the same issues in his day too !

# ~ # ~ #

The whole idea of convenience to the contractors is

more valued than Code compliance, seems to be the

politically & culturally correct norms.........Enforcement

of the legally adopted Codes & Standards, for some,

...seems to be in theory only.

Hammurabi had the same issues in his day too !

# ~ # ~ #

tmurray

SAWHORSE

I don't do electrical, but I've seen hundreds of panels here and have never seen more than one wire per knockout (that I've noticed I guess). Moreover, I have not seen cables bundled at all. wires are individually run down the wall, stapled, and run at a right angle into to panel one by one.312.5(C) Cables.

Where cable is used, each cable shall be secured to the cabinet, cutout box, or meter socket enclosure.

This is from the handbook:

View attachment 9448

This is something that every electrician should learn early in their career. If they learn it from me it’s a bitter pill to swallow. I am okay with that. The rub is that it can be such a bitch to fix. The workman wants to hear from me why fifteen cables in a clamp is a safety issue worth the grief. I hear, “Can you let it goe this time?” If I let it go this time why would the correction have any merit next time….and there will be a next time.

redeyedfly

REGISTERED

Must be a local thing. I see multiple wires per KO clamp typically all coming out the top. The very common 3/8" cable clamps allow up to (3) 14/2 in one clamp.I don't do electrical, but I've seen hundreds of panels here and have never seen more than one wire per knockout (that I've noticed I guess). Moreover, I have not seen cables bundled at all. wires are individually run down the wall, stapled, and run at a right angle into to panel one by one.

MtnArch

SAWHORSE

Easy Christmas light access! Looks like some of the outrigger ends may need to be cut off at the fascia line, too.

The inspection was for a final of a water main to an apartment building. The pipe size has increased so the original ground clamp is too small. For that reason, the plumber ignored the clamp. I had to tell him to replace the clamp.

The plumber installed almost the correct clamp. It is not too much worse than the original clamp so it is acceptable...well that and the armor is short. I then had to tell the plumber to seal the wall.

He took care of it. The clamp picture and the caulk picture were sent to my phone so no return trips were necessary.

The plumber installed almost the correct clamp. It is not too much worse than the original clamp so it is acceptable...well that and the armor is short. I then had to tell the plumber to seal the wall.

He took care of it. The clamp picture and the caulk picture were sent to my phone so no return trips were necessary.

Last edited:

The job is a furnace and AC.

The contractor and the owner were both upset because they had to wait for me to arrive. The story is that today was the fourth inspection. The AC has no equipment ground with the feeder. The equipment ground from the condenser to the disconnect is a red wire with white tape.

The dwelling is so large that it has to be called a dwelling and not a house. There is a furnace and I know that because there is a correction regarding a sediment trap and the apparently the B-vent has a downward slope. The contractor's representative didn't know where the attic access is located so no ladder was set up....or perhaps he thought I was just going to sign off on the job since this was the fourth inspection.

Thje owner showed us a two by two foot plywood hatch in the garage wall and said that the furnace is behind that. He had to move a car that was in the way of where the ladder had to be but after five minutes of failing to start the car he summoned his wife and she started the car. He said that the car knows the difference between him and her. Well then the workman removed a bunch of screws and the plywood. He said that he sees nothing but duct for about thirty feet and then there is a turn. So the furnace must be around the bend. I didn't go looking for it.

I told the workman that his company has no room to complain but the owner had removed himself and got the message from the correction slip. I anticipate a complaint.

Oh and to get to the AC disconnect it was a tight squeeze between two condensers, a tree and some bushes. My back got scratched and my shirt was torn. Had I been the first inspector that would have been the first correction.

The contractor and the owner were both upset because they had to wait for me to arrive. The story is that today was the fourth inspection. The AC has no equipment ground with the feeder. The equipment ground from the condenser to the disconnect is a red wire with white tape.

The dwelling is so large that it has to be called a dwelling and not a house. There is a furnace and I know that because there is a correction regarding a sediment trap and the apparently the B-vent has a downward slope. The contractor's representative didn't know where the attic access is located so no ladder was set up....or perhaps he thought I was just going to sign off on the job since this was the fourth inspection.

Thje owner showed us a two by two foot plywood hatch in the garage wall and said that the furnace is behind that. He had to move a car that was in the way of where the ladder had to be but after five minutes of failing to start the car he summoned his wife and she started the car. He said that the car knows the difference between him and her. Well then the workman removed a bunch of screws and the plywood. He said that he sees nothing but duct for about thirty feet and then there is a turn. So the furnace must be around the bend. I didn't go looking for it.

I told the workman that his company has no room to complain but the owner had removed himself and got the message from the correction slip. I anticipate a complaint.

Oh and to get to the AC disconnect it was a tight squeeze between two condensers, a tree and some bushes. My back got scratched and my shirt was torn. Had I been the first inspector that would have been the first correction.

Last edited:

The inspection was for a swimming pool final. The car gate is the barrier to the pool. The car gate was approved at the pre-plaster inspection. The contractor stated that a condition of approval is that the gate be electric and close automaticaly with a thirty second delay. There will be thirty seconds to get the car past the gate because it will close ...blocked or not. I found plenty of other corrections so I didn't have to turn it down just because of the gate.

The panel is held up by an 1.5" pvc pipe. It will move with the wind. Well until the two sheet metal screws pull out.

The junction box has already bent to the wind.

The panel is held up by an 1.5" pvc pipe. It will move with the wind. Well until the two sheet metal screws pull out.

The junction box has already bent to the wind.

Last edited:

steveray

SAWHORSE

What's a little eccentric loading between friends?

This thread became soooo off topic that I placed a reply here where it wouldn't matter.

The topic became what a lousy inspector does when he's bored. If you don't believe me take a look at the thread.

Here is an example of a no code violation, violation.

The inspection was for a reroof final. The two halves of the building come together in a less than attractive manner. The valley is skewed to the left. It should start at the top in the picture and the bottom should line up near the rear tire on the truck. The structure is not balanced ... the feng shui is whacked.

You can see that the valley was cut from the right side.....the side that leans into the flow. Can I get a code for that wrong way this was done? Help me out with that.

The correction said, "Create a valley that sheds water instead of bucking water." Sheds and bucking are not found in the code as they relate to a roof valley.

Had the cut been made coming from the left the only wrong would be the ugly. So there you have it. I didn't invent a code but I did write a correction with no code (so far).

The inspection was yesterday at a city where I was a temp so I’ll not find out if the contractor complied.

The topic became what a lousy inspector does when he's bored. If you don't believe me take a look at the thread.

Here is an example of a no code violation, violation.

The inspection was for a reroof final. The two halves of the building come together in a less than attractive manner. The valley is skewed to the left. It should start at the top in the picture and the bottom should line up near the rear tire on the truck. The structure is not balanced ... the feng shui is whacked.

You can see that the valley was cut from the right side.....the side that leans into the flow. Can I get a code for that wrong way this was done? Help me out with that.

The correction said, "Create a valley that sheds water instead of bucking water." Sheds and bucking are not found in the code as they relate to a roof valley.

Had the cut been made coming from the left the only wrong would be the ugly. So there you have it. I didn't invent a code but I did write a correction with no code (so far).

The inspection was yesterday at a city where I was a temp so I’ll not find out if the contractor complied.

Last edited:

I didn’t notice that….The set screw EMT had my attention. This is why I relish posting pictures. The job was a final inspection for an ADU. I wrote twenty corrections and the changes coming to the electrical might be worth the return trip.....but my time in thst city is short so I'll never see it.At least the cover on the LB won’t fall off.

Last edited: