-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

steveray

SAWHORSE

And the bolt too unless you are considering that bonded through the base....No limit to metallic part sizes for the 5' stuff like there is for pool structure<4"....

Those meter main panels are usually listed for use as service equipment only, with a permanently bonded neutral, so am assuming someone added the insulated neutral. You going to let it fly? What did they use to jumper the meter jaws? Have seen a kit made for the purpose but was not insulated.

Since do not see a edit button, forgot to comment about the fine roof jack install, & roof shingle patching, comp roofs are pretty easy to do a nice job cutting in roof jacks into, which they failed miserably by using wet patch, & mixing architectural & 3-tab shingles is always a nice touch,  a nightmare for whoever paid a large sum to have it done.

a nightmare for whoever paid a large sum to have it done.

fatboy

Administrator

What would you say is the estimated cost from a plan review screen, review software, permitting software, field I-pads etc.?

Since do not see a edit button, forgot to comment about the fine roof jack install, & roof shingle patching, comp roofs are pretty easy to do a nice job cutting in roof jacks into, which they failed miserably by using wet patch, & mixing architectural & 3-tab shingles is always a nice touch,a nightmare for whoever paid a large sum to have it done.

Join forces as a sawhorse, and you get some extra perks!

Well then, it appears that the person in charge has overstepped their bounds with this one. While there are ways to go about transforming some service panels to a sub-panel, not entirely legal mind you but there are ways.....This is not one of them. Does anyone know of a UL listing for a meter socket bypass. What Standard would apply? I am not 100% sure that there is no listed meter socket bypass. I am convinced that if there is...one, it's not this one and two, it would be for a temporary use.Those meter main panels are usually listed for use as service equipment only, with a permanently bonded neutral, so am assuming someone added the insulated neutral. You going to let it fly? What did they use to jumper the meter jaws? Have seen a kit made for the purpose but was not insulated.

Last edited:

Looks like the mast used to be to the right and lower than the current location. About where the half-moon cut is in the shingle. And then they used 3-tab to patch the old hole., forgot to comment about the fine roof jack install,

steveray

SAWHORSE

I think milbank makes one...ran across it once....Does anyone know of a UL listing for a meter socket bypass. What Standard would apply? I am not 100% sure that there is no listed meter socket bypass. I am convinced that if there is...one, it's not this one and two, it would be for a temporary use.

steveray

SAWHORSE

1MMJCK | Eaton meter stack meter jumper and cover | Eaton

1MMJCK - Eaton meter stack meter jumper and cover, Meter jumper and cover, 1MP, 1MM, and 3MM modular metering stacks

Maybe....

mtlogcabin

SAWHORSE

Mtlog,Shouldn't the wire with the red marking be on the left and the black on the right isn't that the correct way to do it? Not sure if it is code or just industry standard

View attachment 7245

Please provide additional commentary, South wire has the red stripe on their wire, I have not seen that yet, here they will use red and white tape.

Should that service have a bonding nut?

steveray

SAWHORSE

Yep....and shirley they don't tell the homeowner that they need a permit to remove and reinstall the panels when they get the roof permit next year....

Doing virtual inspections limits my ability to tell people the truth. Had I been there I would have said it just like it reads. Putting the same words in writing is considered being disrespectful and I get chewed out.....like that makes a difference.

18541 ******* was scheduled for an inspection of corrections related to a service panel upgrade on 12-18-2020. It has been a long day. It is almost four o'clock. I am tired. And then I got to your job. Oh my goodness what a mess. I have no words for the service mast roof flashing. The service entrance conduit needs to be bonded to the enclosure and you made every effort to isolate it....Teflon tape, a rubber gasket and sheet metal screws no less. The grounding electrode conductor is wrapped in tape....well at least you used electrical tape.

So I am stopping now. It is Friday and I might pick it up over the weekend but whatever I do I am convinced that it won't be enough.

18541 ******* was scheduled for an inspection of corrections related to a service panel upgrade on 12-18-2020. It has been a long day. It is almost four o'clock. I am tired. And then I got to your job. Oh my goodness what a mess. I have no words for the service mast roof flashing. The service entrance conduit needs to be bonded to the enclosure and you made every effort to isolate it....Teflon tape, a rubber gasket and sheet metal screws no less. The grounding electrode conductor is wrapped in tape....well at least you used electrical tape.

So I am stopping now. It is Friday and I might pick it up over the weekend but whatever I do I am convinced that it won't be enough.

Last edited:

Almost looks like a plumbing reducer screwed into the hub, that style of hub also does not use a gasket, the enclosure opening hole has a upturned flange in the sheet metal to shed water, and as e hilton mentioned the screws are wrong, OEM screws supplied with the hub have machine threads, 10-32, 1/4-20, or 1/4-28. Plus the wrong ground clamp used with armored ground cable, & the tape. Do you ever see good workmanship?

That style hub is used by Anchor, Circle AW (B-Line), & others, GE*, & Midwest (GE owns Midwest), use a similar style hub, but the mounting holes have different center to center mounting hole measurements.

*Should I say ABB? They own that former GE division now.

They own that former GE division now.

That style hub is used by Anchor, Circle AW (B-Line), & others, GE*, & Midwest (GE owns Midwest), use a similar style hub, but the mounting holes have different center to center mounting hole measurements.

*Should I say ABB?

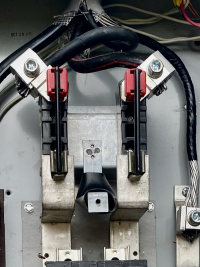

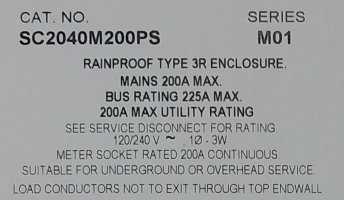

The first inspection revealed four conduit punched through the top endwall.

The last line says that this is not permitted. So did the correction that I wrote.

At the next inspection I found their idea of a fix.

When I asked to see what was used to seal the top I was shown plastic plugs. Within short order the workman was shouting at me. I ended the face time call and within five minutes I got a call from my office manager. It seems that I have upset a contractor.

The last line says that this is not permitted. So did the correction that I wrote.

At the next inspection I found their idea of a fix.

When I asked to see what was used to seal the top I was shown plastic plugs. Within short order the workman was shouting at me. I ended the face time call and within five minutes I got a call from my office manager. It seems that I have upset a contractor.

Last edited by a moderator:

jar546

CBO

Chris works with some guys that would have done both the before and the after

jar546

CBO

The more I look at this thread, the more I am reminded of Pennsylvania.

Are the load conductors still entering the box too high on the wall of the box? I vaguely remember there being a manufacturer rule about that, but I could be confused.The first inspection revealed four conduit punched through the top endwall.

View attachment 7263

The last line says that this is not permitted. So did the correction that I wrote.

View attachment 7264

At the next inspection I found their idea of a fix.

View attachment 7266

When I asked to see what was used to seal the top I was shown plastic plugs. Within short order the workman was shouting at me. I ended the face time call and within five minutes I got a call from my office manager. It seems that In have upset a contractor.

Technically, the listing of the 3R enclosure has been voided. I say technically because if you ask Schneider Electric for a letter they will tell you that the manufacturer provided a sufficient number of knockouts and drilling/punching holes voids the 3R listing. If you just ask Schneider for an opinion without a letter you get a different answer. As long as the 3R feature is maintained with rain-tight entries they are forgiven the fact that it voids a listing.Are the load conductors still entering the box too high on the wall of the box? I vaguely remember there being a manufacturer rule about that, but I could be confused.

The label pretty much says that. It states that load conductors are not to exit through the endwall. There's no knockouts in the endwall....so if the issue were that only knockouts are allowed to be used and drilling/punching holes is outlawed it would not need to mention the endwall. Since it does mention the endwall where there is no knockouts but not the sidewall where there is a ko one could extrapolate his way into drilling the sidewall with abandon.