-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

fatboy

Administrator

WOW! Don't know what else to say to that, other than what the heck is that all about?

steveray

SAWHORSE

It's for drainage...

What I find odd about this is that it happened within a day or two of the post just before it. The discussion was about violating a listing by drilling holes and then this contractor hit one out of the park.

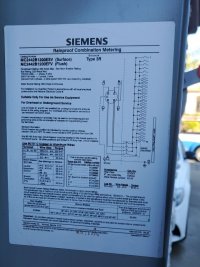

If the entries are above live parts, hubs, sealing locknuts, or other means, must be used to prevent the entry of water into the enclosure, and those punched holes are above live parts.Technically, the listing of the 3R enclosure has been voided. I say technically because if you ask Schneider Electric for a letter they will tell you that the manufacturer provided a sufficient number of knockouts and drilling/punching holes voids the 3R listing. If you just ask Schneider for an opinion without a letter you get a different answer. As long as the 3R feature is maintained with rain-tight entries they are forgiven the fact that it voids a listing.

The label pretty much says that. It states that load conductors are not to exit through the endwall. There's no knockouts in the endwall....so if the issue were that only knockouts are allowed to be used and drilling/punching holes is outlawed it would not need to mention the endwall. Since it does mention the endwall where there is no knockouts but not the sidewall where there is a ko one could extrapolate his way into drilling the sidewall with abandon.

What has me wondering is what was done with the service entrance conductors in the last photos? Looks like a UG only panel, normally power companies do not like them in LB's. & they sure went crazy with the gutters.

The damage is in the section just below the meter. The service lateral comes in at the section just to the left.What has me wondering is what was done with the service entrance conductors in the last photos? Looks like a UG only panel, normally power companies do not like them in LB's. & they sure went crazy with the gutters.Without photos with the covers off it is hard to tell what they were up to.

fatboy

Administrator

Any clown who does this, should be tarred and feathered themselves! Friggen hacks, won't even begin to call them a "tradesperson".

If this was my roof, I would get a professional roofer in there, get it fixed right, and deduct it from the bill for the service work. Settle it in small claims court.

Mechanical people are just as bad sometimes.

EDIT: I went back, I see this is tied to the thread above, where they butchered the enclosure also.......go figure.

If this was my roof, I would get a professional roofer in there, get it fixed right, and deduct it from the bill for the service work. Settle it in small claims court.

Mechanical people are just as bad sometimes.

EDIT: I went back, I see this is tied to the thread above, where they butchered the enclosure also.......go figure.

I see the same thing, to add to it there is a spot on the bar to accept it without the need for any accessories.Am i seeing that right? The copper wires that come up through the middle knockout ... twist around ... but aren’t attached to anything.

Yes that was done that way. Notice the cable entering the back of the panel. I haven't done an inspection yet and don't have enough pictures to know, but I suspect that the panel is surface mounted and the cable out the back is a deal breaker. So when it is redone there should be a better outcome with the grounding.Am i seeing that right? The copper wires that come up through the middle knockout ... twist around ... but aren’t attached to anything.

The job is a service panel upgrade. The picture was provided to demonstrate that a jumper was installed at the water heater from cold to hot to gas. When there armored wire one might assume that they are relatively new at this type of work. I know that making assumptions is not appropriate so I just assume that nobody ever knows what they are doing.

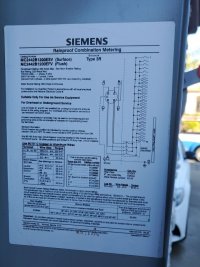

The project is tesla two storage batteries. All of the load that was fed from the main panel has been moved to a 200amp selected load panel. They have installed a 175 amp breaker in the main that goes through a gateway to power the selected load. The main panel label limits the maximum permitted breaker to 100amps.

https://www.dropbox.com/s/12w6vrgkwp1xdpj/IMG_0101.JPG?dl=0

This was an underground plumbing inspection for a slab home. Although it's hard to tell from the photo, the drain pipe that feeds into the sewer was poured directly into the footing, with no sleeve or relieving arch. The pipe is just set right into the concrete.

2018 IRC P2603.4

This was an underground plumbing inspection for a slab home. Although it's hard to tell from the photo, the drain pipe that feeds into the sewer was poured directly into the footing, with no sleeve or relieving arch. The pipe is just set right into the concrete.

2018 IRC P2603.4

It depends on which manager gets the contractor's complaint....that's if the contractor complains. Some managers will forgive all manner of deficiency as long as it was there before the contractor got there. Other managers know a situation when they see one.Can you reject the furnace installation because the vent is not connected to a proper vent stack?

I don't know about tags on gas connectors. Please enlighten me. I suppose there's a code for that.Did you gig em for a flex GAS line without a tag or is that not required or enforced anymore?

May not be a CA requirement?

2018 IFGC 401.9 shall bear the identification of the manufacture.

411.1 (4) listed and labeled appliance connectors

I guess if the CSST appliance connector has this ANSI Z21.24/CGA 6.10 stamped on it somewhere, you can approve?

Just didn't see the tag in the pic that has a lot of information on it in regards to installation and certification.

2018 IFGC 401.9 shall bear the identification of the manufacture.

411.1 (4) listed and labeled appliance connectors

I guess if the CSST appliance connector has this ANSI Z21.24/CGA 6.10 stamped on it somewhere, you can approve?

Just didn't see the tag in the pic that has a lot of information on it in regards to installation and certification.