steveray

SAWHORSE

Hunh.....Finally something where IPC is tighter than UPC/ CPC....

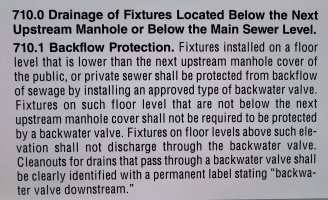

P3008.1 Sewage backflow. Where the flood level rims of

plumbing fixtures are below the elevation of the manhole

cover of the next upstream manhole in the public sewer, the

fixtures shall be protected by a backwater valve installed in

the building drain, branch of the building drain or horizontal

branch serving such fixtures. Plumbing fixtures having flood

level rims above the elevation of the manhole cover of the

next upstream manhole in the public sewer shall not discharge

through a backwater valve.

Unless you are just saying it is a flat area and that is why it is not required?

P3008.1 Sewage backflow. Where the flood level rims of

plumbing fixtures are below the elevation of the manhole

cover of the next upstream manhole in the public sewer, the

fixtures shall be protected by a backwater valve installed in

the building drain, branch of the building drain or horizontal

branch serving such fixtures. Plumbing fixtures having flood

level rims above the elevation of the manhole cover of the

next upstream manhole in the public sewer shall not discharge

through a backwater valve.

Unless you are just saying it is a flat area and that is why it is not required?