My neighbor had an inspection for rooftop solar yesterday. In California the AHJ is allowed to perform just one inspection for solar and that is the final inspection. The inspector was there for less than four minutes. The house is two story with five bedrooms and there wasn't time enough to verify the smoke and CO alarms much less perform an inspection of the solar. I don't know if the work passed inspection but the contractor and owner were all smiles.

-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

I assume that the A35 is acting as a shear transfer.Whats the purpose of the adjustable connectors above the window … the ones that have been mashed flat?

Force Transfer Around Openings.... it is an engineered design that allows for partial credit of shear resistance from the sheathing around the opening.Whats the purpose of the adjustable connectors above the window … the ones that have been mashed flat?

Learn more from APA @ https://www.apawood.org/ftao

Sorry... if you were referring to the connectors at the rim board, it is likely an additional connection from the rim board to the top/bottom plates of the wall above/below. If they are Simpson A35, they should have been installed on the inside of the rim where they would not have been smashed flat. Looks suspect. But it is clearly an engineered design, so need to know what the engineer designed to know more for sure.Whats the purpose of the adjustable connectors above the window … the ones that have been mashed flat?

Force Transfer Around Openings.... it is an engineered design that allows for partial credit of shear resistance from the sheathing around the opening.

Learn more from APA @ https://www.apawood.org/ftao

The staircase in the window is why I posted the picture.Hope they ordered a window with tempered glass?

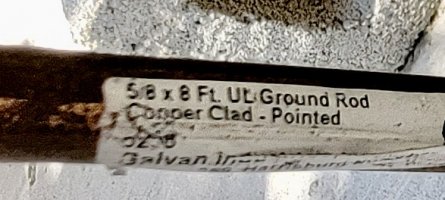

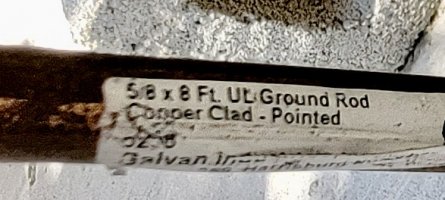

250.53(G) Rod and Pipe Electrodes.

The electrode shall be installed such that at least 2.44 m (8 ft) of length is in contact with the soil. It shall be driven to a depth of not less than 2.44 m (8 ft).

This was done by a licensed general contractor. There is ample evidence that the contractor should not be performing electrical work. Had anyone involved known much about the electrical code requirements the rod would be driven to a couple inches above the concrete. While that is short of 8' it has been an accepted practice forever.

The label is the true indication that they are clueless and not because they didn't read it. Since the label is present, the typical reply, "That's a ten foot long rod" will not suffice as usual. They didn't know that there is a ten foot rod available and perhaps they would not lie even if they did. Now the GEC and armor are too short but luckily, there is just one rod.

The electrode shall be installed such that at least 2.44 m (8 ft) of length is in contact with the soil. It shall be driven to a depth of not less than 2.44 m (8 ft).

This was done by a licensed general contractor. There is ample evidence that the contractor should not be performing electrical work. Had anyone involved known much about the electrical code requirements the rod would be driven to a couple inches above the concrete. While that is short of 8' it has been an accepted practice forever.

The label is the true indication that they are clueless and not because they didn't read it. Since the label is present, the typical reply, "That's a ten foot long rod" will not suffice as usual. They didn't know that there is a ten foot rod available and perhaps they would not lie even if they did. Now the GEC and armor are too short but luckily, there is just one rod.

Besides the rod not driven far enough, do you have testing results of 25 ohms or less so that they can only drive one rod? See 250.53(2) 2017 NEC. It also looks like that condensing unit may be supplied with flexible cord, but can't tell for sure.

They wouldn’t know what an ohm is. The lucky part of the single rod is that there is less wast of #4 GEC and armor. But looking at the picture I think that I could be wrong about the single rod. The GEC doesn’t stop at the rod. ….but maybe it continues to the water main. Who knows….Besides the rod not driven far enough, do you have testing results of 25 ohms or less so that they can only drive one rod?

The picture was sent to me by an inspector and the condenser was not mentioned by him.

Last edited:

250.53(2) still applies, no test a 2nd rod is required & is the quickest & cheapest way to comply, the testing equipment is expensive and need to be qualified to perform the testing.They wouldn’t know what an ohm is. The lucky part of the single rod is that there is less wast of #4 GEC and armor. But looking at the picture I think that I was wrong about the single rod. The GEC doesn’t stop at the rod.

The picture was sent to me by an inspector and the condenser was not mentioned by him.

I have witnessed the test. https://www.fluke.com/en-us/learn/blog/grounding/earth-ground-fall-potentialthe testing equipment is expensive and need to be qualified to perform the testing.

I have encountered this device. I contacted Fluke and I was told that the only true measurement of ground rod resistance is the three point fall-of-potential test. https://www.testequity.com/product/...vYQizpxqImyBapj06_exoBCcdoCIsqwoaAsM8EALw_wcB

Inspector Gadget

SAWHORSE

I find this slightly shocking. Dunno about your codes of conduct in the U.S., but it's drilled into our heads (and now encapsulated in law) that we are not to provide design guidance. The most I'd expect is "submit designs that comply with [insert code or standard reference.]

That correction notice is flippen ridiculous! The contractor should scream, how about something I can read. I would have an inspector on the carpet in front of me.

Charge the AHJ for translation from Coptic to English.

That's ingenious.

They wouldn’t know what an ohm is.

People are so resistant to knowledge.

Thank you, I will be back later this week.

Mech

REGISTERED

ICE said:

They wouldn't know what an ohm is.

People are so resistant to knowledge.

Thank you, I will be back later this week.

What units are used to measure a person's resistance to change? Uhms?

Inspector Gadget

SAWHORSE

More like Whats?What units are used to measure a person's resistance to change? Uhms?

Dolts?What units are used to measure a person's resistance to change? Uhms?

Inspector Gift

SAWHORSE

It looks like they patched a hole next to the rod? The patch material matches what is spread around the new ground rod. I'm guessing that they tried to drill a hole and hit rebar or something else, so they tried again 5 inches away.

View attachment 9148

mtlogcabin

SAWHORSE

They just forgot to cut it off closer to the concrete