-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

Nope.

This happened to an inspector. The inspection was for solar. The inspector was met but the owner. The owner opened the garage door and there sat everything ... racking, panels, inverter, etc. The owner asked the inspector to verify that everything that would be required was present.

The inspector told the owner that he should ask the contractor to do that. The owner told the inspector that there is no contractor and it is an owner/builder project. The owner told the inspector that it is the inspector's job to explain how to install the PV system. The inspector said that he does not have that kind of time to spend on a job and it is not his responsibility. The owner asked the inspector to come on weekends.

The inspector told the owner that he should ask the contractor to do that. The owner told the inspector that there is no contractor and it is an owner/builder project. The owner told the inspector that it is the inspector's job to explain how to install the PV system. The inspector said that he does not have that kind of time to spend on a job and it is not his responsibility. The owner asked the inspector to come on weekends.

Last edited:

wwhitney

REGISTERED

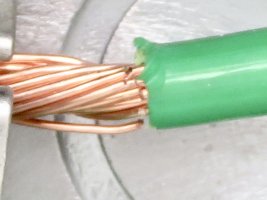

So the only problem is that if the underground water service is metallic and in contact with the earth for 10', the water pipe needs to be used as an electrode by making a connection to it within 5' of entering the house.Service upgrade. Licensed electrical contractor. This Connection to the gas pipe and a ufer are the grounding electrode system. Five feet from the gas meter is the copper main water service pipe. The contractor says that the gas pipe is connected to the cold water pipe at the water heater.

Calling the gas pipe an electrode in the configuration shown is a misnomer--the gas meter has a dielectric fitting on the utility side, so the customer's gas piping is electrically isolated from the underground gas piping. The customer gas piping system is required to be bonded, and the clamp and jumper are one way to do that.

Cheers, Wayne

Dielectric union is not part of the electrician's vocabulary. He is relying on the gas pipe between the meter and the water heater to reach the water main, hence the description: "grounding electrode system".Calling the gas pipe an electrode in the configuration shown is a misnomer--the gas meter has a dielectric fitting on the utility side, so the customer's gas piping is electrically isolated from the underground gas piping. The customer gas piping system is required to be bonded, and the clamp and jumper are one way to do that.

Of course, the electrician was not actually intending to reach the water main. Nor did he bond the hot water pipe at the water heater. The usual requirement is a jumper between the cold, hot and gas pipes at the water heater. The gas can be considered bonded by the EGC of an appliance such as a gas fired furnace however there isn't always a forced air unit and in the effort to speed up the inspection process we have determined that the aforementioned jumper is the best choice.

The hodgepodge code enforcement of Southern California produces many weird results such as this. The rest of the work was stellar. It was done with attention to detail. I was met by the electrical contractor's wife and she was on a facetime call with the husband. He said, and I believe him, that he has been told to do exactly this by inspectors. The evidence of this is the fact that the water main is a few feet away and now he must return for a correction. Well he did miss the surge protection so there's that.

Last edited:

The inspectors job is not to explain how to do the job, it's their job to inspect the work to the applicable codes & standards. I would also see it as a liability issue.This happened to an inspector. The inspection was for solar. The inspector was met but the owner. The owner opened the garage door and there sat everything ... racking, panels, inverter, etc. The owner asked the inspector to verify that everything that would be required was present.

The inspector told the owner that he should ask the contractor to do that. The owner told the inspector that there is no contractor and it is an owner/builder project. The owner told the inspector that it is the inspector's job to explain how to install the PV system. The inspector said that he does not have that kind of time to spend on a job and it is not his responsibility. The owner ask the inspector to come on weekends.

wwhitney

REGISTERED

I do find it odd that the hot-cold-gas jumper at the water heater has seemed to migrate in many CA jurisdictions from being "an easy way to demonstrate compliance" with the bonding requirements to "the only acceptable way to demonstrate compliance".The usual requirement is a jumper between the cold, hot and gas pipes at the water heater. The gas can be considered bonded by the EGC of an appliance such as a gas fired furnace however there isn't always a forced air unit and in the effort to speed up the inspection process we have determined that the aforementioned jumper is the best choice.

As to the gas bonding, what modern gas appliance is available without an EGC? If none, then all that is required by the NEC is to confirm that if there is gas, there is one modern gas appliance; its EGC will bond the gas piping. [Unless there's CSST, then I think one of the other codes may require a bonding jumper elsewhere.]

And then if the principal water piping is PEX rather than metallic, small isolated section of metal piping don't require bonding, so there would be no need for a water heater hot-cold bond. [Or if there's no dielectric union at the water heater; does any code require a dielectric union?]

Obviously noting a hot-cold-gas jumper at the water heater is a quicker to comply with those bonding requirements.

Cheers, Wayne

Unless there's CSST, then I think one of the other codes may require a bonding jumper elsewhere.

This is an old code because I can't copy and paste a newer edition but it is mostly the same today

2013 CPC

1210.15.2 Bonding of CSST Gas Piping. CSST gas piping systems shall be bonded to the electrical service grounding electrode system. The bonding jumper shall connect to a metallic pipe or fitting between the point of delivery and the first downstream CSST fitting. The bonding jumper shall be not smaller than 6 AWG copper wire or equivalent. Gas piping systems that contain one or more segments of CSST shall be bonded in accordance with this section. [NFPA 54-12:7.13.2]

1210.15.3 Grounding Conductor or Electrode. Gas piping shall not be used as a grounding conductor or electrode. [NFPA 54-12:7.13.3]

Wall furnace... and there's a lot of them.As to the gas bonding, what modern gas appliance is available without an EGC?

Last edited:

wwhitney

REGISTERED

The location of the bonding is less stringent, as is an allowance to just rely on the NEC required bonding if all the CSST has an arc-resistant jacket.This is an old code because I can't copy and paste a newer edition but it is mostly the same today

Ah, right, or any appliance that doesn't require an electrical circuit. Of course, one could argue that if the only gas appliances installed are ones without any electrical connections, then often there would be no "gas piping system that is likely to become energized." Depending on the routing and proximity of the gas piping and the electrical circuits.Wall furnace... and there's a lot of them.

Thanks for the references.

Cheers, Wayne

I am aware of the claims by TracPipe CounterStrike when it comes to bonding. It would be believable if the code recognized the product such as has been done with FVIR water heaters.The location of the bonding is less stringent, as is an allowance to just rely on the NEC required bonding if all the CSST has an arc-resistant jacket.

The following is from the TracPipe web site:

At the hub of the installation is a multiport manifold. From there CounterStrike® can go anywhere – around obstructions, across attics, or between joists and studs. You pull it just like electric wiring. Protect it with striker plates and your options are endless.

Adding a last minute appliance in a CounterStrike® house? No need to rip out that perfect drywall. Grab some AutoSnap® fittings and a tee – you can bend CounterStrike® with your hands and it holds its shape. Add-ons have never been easier.

Doing a renovation and need to maintain architectural integrity? No problem, just connect into existing black iron pipe and feed CounterStrike® up to the new master bedroom fireplace or second floor laundry.

The installation instructions are clear on protecting the tubing yet here is the advice to fish the product with no protection.

This is from CounterStrike installation instructions:

The TracPipe® CounterStrike® gas piping system shall be bonded in accordance with these instructions

and local codes. In the event of a conflict between these instructions and local codes, the local codes shall control. The piping system is not to be used as a grounding conductor or electrode for an electrical system.

Installation instructions are supposed to be in conformance with the listing however, I have found multiple instances where that is not true. When I hear the word "resistant" I am not impressed. The manufacture states that CounterStrike is 400 times better than generic CSST that is bonded with the code described jumper when it comes to arcing. I guess 1000 times better sounds trite. In case you haven't noticed, I don't trust the manufacturers..... that and the code requires the bonding jumper.

then often there would be no "gas piping system that is likely to become energized."

Likely to become energized has been a topic of discussion. CSST is not pipe...it is tubing used for piping gas.

250.104(B) Other Metal Piping. If installed in or attached to a building or structure, a metal piping system(s), including gas piping, that is likely to become energized shall be bonded to any of the following:

Last edited:

I’m guessing that the HO read that comment on a diy solar forum somewhere.The inspectors job is not to explain how to do the job, it's their job to inspect the work to the applicable codes & standards. I would also see it as a liability issue.

Inspector Gadget

SAWHORSE

You wouldn't permit anything except balusters? Not solid panels or mesh nor anything else but balusters?

I thought there were graspable rails on both sides and can't see end of ramp.

a) We'd accept solid panels, yes. Or safety glass/plexi - anything that can meet the guard loading requirements.

b) Our Codes require both a guard (at 107 cm/42") if the height above the surrounding surface is >60 cm (24") and a continually graspable handrail at between 86.5 and 96.5 cm height. So, the answer is no.

The inspectors job is not to explain how to do the job, it's their job to inspect the work to the applicable codes & standards. I would also see it as a liability issue.

Our regulations are now quite clear: we are not allowed, by law, to provide design guidance.

tmurray

SAWHORSE

The other issue with the inspector directing work is the violation of the 3rd party inspection principle. It's really hard to inspect your own work.Our regulations are now quite clear: we are not allowed, by law, to provide design guidance.

Inspector Gadget

SAWHORSE

The other issue with the inspector directing work is the violation of the 3rd party inspection principle. It's really hard to inspect your own work.

Ahyup. As a former journalist, I can testify that it's really difficult to prufreed youre own riting.

bill1952

SAWHORSE

Yup. I forget that it's only for assembly aisle stairs and aisle ramps where the top rail of a guard is permitted to be the handrail. (And that is thanks to a Canadian!) The problem of only working on assembly occupancies.b) Our Codes require both a guard (at 107 cm/42") if the height above the surrounding surface is >60 cm (24") and a continually graspable handrail at between 86.5 and 96.5 cm height. So, the answer is no.

Inspector Gadget

SAWHORSE

Yup. I forget that it's only for assembly aisle stairs and aisle ramps where the top rail of a guard is permitted to be the handrail. (And that is thanks to a Canadian!) The problem of only working on assembly occupancies.

I've largely been working on non-residential files of late; I had to jog my brain and remember what the (unique) differences were for a simple single-family dwelling.

I think there's strengths and weaknesses to specializing, but more strengths than weaknesses.

bill1952

SAWHORSE

I started working backstage in 6th grade - almost 60 years ago - and one of those choices I don't regret at all.I've largely been working on non-residential files of late; I had to jog my brain and remember what the (unique) differences were for a simple single-family dwelling.

I think there's strengths and weaknesses to specializing, but more strengths than weaknesses.

Inspector Gadget

SAWHORSE

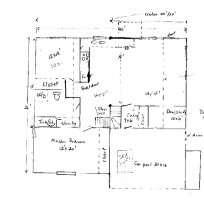

Dang! That is almost the proverbial drawn on a napkin design.This was recently submitted as the "plan" for a new home, which I *think* is supposed to be two stories.

MtnArch

SAWHORSE

What's wrong with this? It worked back in the 1950's!

Zeke

REGISTERED

Indeed. Up until the 70's in not much better form. I used to hand draw plans, have copied at the blue print place and submit them. No engineering for a room add or major remodel including spans. Just put the table on the plan.What's wrong with this? It worked back in the 1950's!

We've gone too far but given what I see for builders these days, I can't fault it.

Paul Sweet

SAWHORSE

A 16' deep carport? He must drive a SmartCar.

Zeke

REGISTERED

^^^ hah! Substandard for sure but most cars sold now except full size fit. Talking about all the little 4-door SUV types. I think they are the majority now even if the F150 sells millions.