Appearances can be deceiving.Apparently everyone there were all born that way.

-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

mtlogcabin

SAWHORSE

When you don't do it right

www.ktvq.com

www.ktvq.com

Building under construction collapses in west Billings

A construction project crumble to the ground Monday afternoon near Shiloh Road and Avenue C. No one was injured.

When you don't do it right

View attachment 10834

Building under construction collapses in west Billings

A construction project crumble to the ground Monday afternoon near Shiloh Road and Avenue C. No one was injured.www.ktvq.com

Mr. Inspector

SAWHORSE

Just failed an inspection for a famous chicken restaurant with a flat roof that had the trusses upside down

Inspector Gadget

SAWHORSE

wwhitney

REGISTERED

The second photo shows a missing set screw on an EMT connector, I believe, which would be wrong.Is it just me or does it look like there's something wrong here?

But the first photo shows a squeeze connector on MC cable (or is it FMC or something else?), so I don't see the problem. There is a hole that could take a setscrew, which I don't believe a squeeze connector typically uses, so maybe that connector is some sort of combo EMT/MC connector, and you only use the setscrew when using it with EMT? That's total speculation, not sure if that product exists.

Cheers, Wayne

wwhitney

REGISTERED

That's just the way a squeeze connector is made and used.What about the jagged metal? It appears that it is torn apart.

The squeeze connector has a full ring portion (at the top of the picture) that connects to the box, and a split ring portion used as a clamp on the cable armor. They are connected by a thick post that is on the backside of the photo and not visible. They are also connected, just for manufacturing purposes, by the thin portion now showing as cracked in the photo. That thin portion is expected to fail when you tighten the clamp on the cable armor, to allow the split ring portion to because a smaller diameter and do the clamping.

Cheers, Wayne

wwhitney

REGISTERED

to becometo because a smaller diameter

Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,572

Once had the door answered by a man wearing dreadlocks and beads in his beard.The number of stories about people answering the door naked is hilarious. Im still waiting on my first, although I was inspecting a lingerie store and the owner showed me around in her bra. So that was cool.

That was all he was wearing.

The call was to look at a tub he installed in his bedroom. Quickest inspection ever.

Wonder if they used red heads? One reason I like jake (screw in style) connectors,

He/She is probably a half-way decent inspector. I mean, at least this is proof that they can read a set of plans and determine if the corresponding construction matches. That's probably better than a fair share of folks currently holding down building inspections.I want some of what he is smoking.

But what this does likely prove is that decent inspection skills cannot make up for a lack of knowledge. The corrections demonstrate a clear lack of background and understanding in the disciplines for which they are inspecting.

Inspector Gadget

SAWHORSE

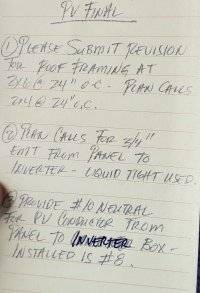

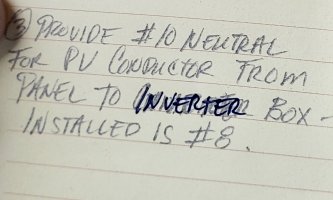

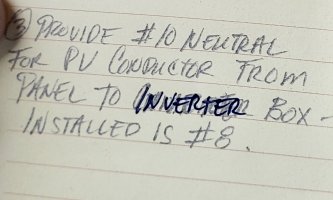

Not sure about #2, but buddy should be smart enough to recognize that a 2x6 is a titch stronger than a 2x4. Unless it was engineered (and even then), wtf?

If this dude is an electrical inspector, buddy should know the ampacity of a #8 is more betterer than #10. Egad.

Maybe the inspector is not saying that it's "wrong" just that they want the plans updated to reflect what actually exists? Just guessing...

Basically, the same concept for #2. Other than the EMT being rigid, the Liquid Tight FMC is a generally superior product.Not sure about #2, but buddy should be smart enough to recognize that a 2x6 is a titch stronger than a 2x4. Unless it was engineered (and even then), wtf?

If this dude is an electrical inspector, buddy should know the ampacity of a #8 is more betterer than #10. Egad.

The inspector is on an extended power trip. He wants to demonstrate that he knows how to read a set of PV plans. He is willing to waste everyone's time with a stupid request. Asking a contractor to remove #8 wire and replace it with #10 is proof enough that he is an menace. The final will be held up for weeks while the revised plans make it through the system and then he will be back at the site hoping for another violation.

bill1952

SAWHORSE

tmurray

SAWHORSE

While I understand the need for accurate plans, I think all this inspector has taught the designer in this case is to put "or better" after each specification in the plans.The inspector is on an extended power trip. He wants to demonstrate that he knows how to read a set of PV plans. He is willing to waste everyone's time with a stupid request. Asking a contractor to remove #8 wire and replace it with #10 is proof enough that he is an menace. The final will be held up for weeks while the revised plans make it through the system and then he will be back at the site hoping for another violation.

A thread about roof sheathing reminded me of one of the darkest days of my life:

What seems like forever ago, I found myself on a construction crew building a farm store in rural Iowa. The frame was all steel. The roof was first layered with 4’x12’ Styrofoam panels. Then came ribbed steel sheets that were 2’ or 3’ wide…I can’t remember exactly but that does not matter for this story.

The crew was made up of farm kids. I was one of the few people there with any construction experience … I was therefor a leader at the ripe old age of 19. As myself and four other young men were laying down the roof, I would walk out on the Styrofoam panels in order to set the next row. I walked where I knew there was a framing support under the Styrofoam. I wasn’t hard to do as the supports followed a straight line.

I took a day off. One of the farm boys tried to be me and stepped at the wrong place and fell to the concrete slab below. He died that day. When I returned there was a rolling scaffold placed below the workers on the roof. The scaffold would limit a fall to about four feet.

I was blamed for the death of the young man because I had been walking the Styrofoam. I should point out that as I was doing so I saw others starting to step out and I stopped them with a stern warning to not do as I do. I didn’t go back to work there after that kid died.

What seems like forever ago, I found myself on a construction crew building a farm store in rural Iowa. The frame was all steel. The roof was first layered with 4’x12’ Styrofoam panels. Then came ribbed steel sheets that were 2’ or 3’ wide…I can’t remember exactly but that does not matter for this story.

The crew was made up of farm kids. I was one of the few people there with any construction experience … I was therefor a leader at the ripe old age of 19. As myself and four other young men were laying down the roof, I would walk out on the Styrofoam panels in order to set the next row. I walked where I knew there was a framing support under the Styrofoam. I wasn’t hard to do as the supports followed a straight line.

I took a day off. One of the farm boys tried to be me and stepped at the wrong place and fell to the concrete slab below. He died that day. When I returned there was a rolling scaffold placed below the workers on the roof. The scaffold would limit a fall to about four feet.

I was blamed for the death of the young man because I had been walking the Styrofoam. I should point out that as I was doing so I saw others starting to step out and I stopped them with a stern warning to not do as I do. I didn’t go back to work there after that kid died.

fatboy

Administrator

That really sucks, I can't even imagine. I would not have returned either.A thread about roof sheathing reminded me of one of the darkest days of my life:

What seems like forever ago, I found myself on a construction crew building a farm store in rural Iowa. The frame was all steel. The roof was first layered with 4’x12’ Styrofoam panels. Then came ribbed steel sheets that were 2’ or 3’ wide…I can’t remember exactly but that does not matter for this story.

The crew was made up of farm kids. I was one of the few people there with any construction experience … I was therefor a leader at the ripe old age of 19. As myself and four other young men were laying down the roof, I would walk out on the Styrofoam panels in order to set the next row. I walked where I knew there was a framing support under the Styrofoam. I wasn’t hard to do as the supports followed a straight line.

I took a day off. One of the farm boys tried to be me and stepped at the wrong place and fell to the concrete slab below. He died that day. When I returned there was a rolling scaffold placed below the workers on the roof. The scaffold would limit a fall to about four feet.

I was blamed for the death of the young man because I had been walking the Styrofoam. I should point out that as I was doing so I saw others starting to step out and I stopped them with a stern warning to not do as I do. I didn’t go back to work there after that kid died.