It is a stuck drill bit.

-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

Inspector Gift

SAWHORSE

Does a drill bit qualify as ground rod?

The installation instructions call for the foam/glue to be painted due to exposure to UV light. I wonder about flammability. There was a time when I was tasked with approving solar racking installation instructions for LA County. This company's effort would not make the cut.Why is this a bad idea, providing the adhesive foam is compatible with the roofing material, stand off and has the sufficient uplift strength.

Lightning arresting system are use adhesive to attach the system to the roof, walk mats are done the same. Trim on cars used double side tape, we hang art on the wall with command strips.

On the face of it, I understand how the product achieved a UL Certificate Of Compliance. The Miami-Dade NOA is another thing altogether.

Technical | How Does The Solar Stack Work | Solar Stack

Learn more about the technical aspects of Solar Stack on our technical page. For engineers, architects, and experienced homeowners.

This is the last paragraph of the warranty:

Except as set forth above, SOLAR STACK INC sells the Products on an “AS IS” basis, which may not be free of errors or defects, SOLAR STACK INC SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES OF ANY KIND, NOR UNDER ANY CIRCUMSTANCE SHALL SOLAR STACK INC BE LIABLE FOR DAMAGES BEYOND THE PRICE OF THE PRODUCT PURCHASED BY PURCHASER, WHETHER IN CONTRACT, IN TORT OR UNDER ANY WARRANTY OR OTHER USE, AND WHETHER OR NOT SAID LOSS, COST, PENALTY OR DAMAGE WAS REASONABLY FORESEEABLE.

Last edited:

steveray

SAWHORSE

I saw that and went looking for the details. I didn't find an answer as to what they were certified to other than UL2703 Safety. However there is a Miami-Dade Notice Of Approval so there is the assumption that a hurricane won't rip it off the building. The installation instructions are so scant on details that I would question whether there is a legitimate Listing or Certificate Of Compliance.

The concept of gluing the array to a roof covering just seems wrong for many reasons.

steveray

SAWHORSE

Shirley it voids the roof warranty.....Pretty sure roll roofing was not designed to hold anything down but itself.....The concept of gluing the array to a roof covering just seems wrong for many reasons.

Paul Sweet

SAWHORSE

The Solar Stack looks like it was installed on a modified bitumen roof with a granulated cap sheet. This or a fully adhered membrane roof should be able to take the uplift. I'd be concerned about an installation on a non-adhered system or a TPO roof that is only fastened at the seams.

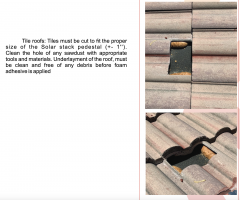

Pg. 10 of the instructions says that roof tiles must be cut out to install the pedestals! I can imagine how many leaks that would cause.

Pg. 10 of the instructions says that roof tiles must be cut out to install the pedestals! I can imagine how many leaks that would cause.

The Solar Stack looks like it was installed on a modified bitumen roof with a granulated cap sheet. This or a fully adhered membrane roof should be able to take the uplift. I'd be concerned about an installation on a non-adhered system or a TPO roof that is only fastened at the seams.

Pg. 10 of the instructions says that roof tiles must be cut out to install the pedestals! I can imagine how many leaks that would cause.

The claim is that there are no roof penetrations yet the tile is compromised. The foam will trap water and the underlayment will be put to the test.... forever. Other racking mounts applied on a tile roof that I have seen all have flashing or the tile removed and a legitimate roof covering installed under the array. This method is not something that I would trust. But hey now, that's just my opinion.

As to the placement on a BUR or shingle roof....there are requirements such as a clean surface with no loose granules. Fat chance. I have seen solar on shot roofs. The installer will blow and go with nary a thought of the installation instructions. It's the Wild West out there. Inspectors are expected to stay out of the way.

Last edited:

How long is that roto hammer spline bit/"ground rod"?

This is located at a large project for condominiums. I was there to inspect the installation of the valves. It took an hour.

When it was done I asked them to energize...The water pressure is 150 psi.

Turns out to be backwards. The top has to be removed, rotated and reinstalled. I got a call from the contractor when I was leaving town. He wanted me to return to the site.

When it was done I asked them to energize...The water pressure is 150 psi.

Turns out to be backwards. The top has to be removed, rotated and reinstalled. I got a call from the contractor when I was leaving town. He wanted me to return to the site.

Is the a/c disconnect too close to the pool?

No and neither is the condenser…three inches to spare. The window frames are vinyl.Is the a/c disconnect too close to the pool?

The solid #6 originates in a panel and hits the first ground rod:Is that a continuous GEC (grounding electrode conductor) system? Or two GEC using the one GE (grounding electrode)?

Trip hazard

Prefer acorn grounding clamp on that application.

"Sometimes that's the best you can get!"

From there the continuous solid #6 hits a second ground rod and continues to the water main:

Last edited:

steveray

SAWHORSE

Not all electricians are smart..... I can't imagine an electrician doing that

If you buy conduit from a major electrical supply house, does every piece have a bar code price tag?Not all electricians are smart....

Msradell

SAWHORSE

NoIf you buy conduit from a major electrical supply house, does every piece have a bar code price tag?

MtnArch

SAWHORSE

But that's where the drawings showed them to be placed!Now that is hard to believe. I can't imagine an electrician doing that and certianly not the pipe-fitter.

View attachment 11139